Place one call and access our extensive inventory of 10,000 new parts and components for all grinder types and brands

Get the Grinder Parts and Components You Need

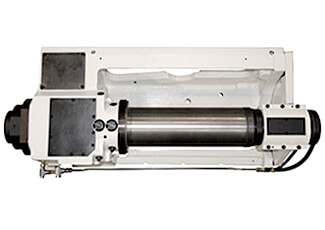

Centerless Regulating Wheel Spindle Assemblies

GCH offers remanufactured regulating wheel spindle assemblies for Cincinnati grinders built from the 1940s onward. To eliminate downtime, GCH offers these components through its exclusive Remanufacturing Exchange Program. Simply tell GCH what you need and we will ship a replacement to you. Install the replacement regulating wheel spindle assembly in your machine and then ship the damaged unit to us for credit. No downtime. No lost production.

GCH Follows Remanufacturing Standards That Meet or Surpass OEM Specifications

- Remanufacturing starts by re-qualifying the regulating wheel housing itself to ensure that the mounting face and the regulating dresser’s mounting face are flat and parallel with the bearing housing bore. Both surfaces are hand-scraped and flaked to new machine alignments and tolerances.

- New ceramic coating is reapplied to the spindles, which are then precision ground to original tolerances.

- All new bronze bearings are individually hand-scraped to the spindle.

- All perishable parts on the regulating wheel spindle assembly are replaced with new parts (sprockets, seals, thrust bearings, etc.).

- New lube lines are installed.

- The completed assembly is run on a specially designed test stand for eight hours to ensure quality and reliability.

- A GCH blue quality assurance tag that includes the job number, remanufacturing date and the mechanic’s identification number is affixed to the component.

Depending on the model, GCH also offers regulating wheel spindle upgrades, such as added outboard support for increased rigidity, or replacement of bronze filmatic bearings with high-precision roller bearings for improved static stiffness.

GCH Tool can also remanufacture regulating wheel spindle assemblies used on centerless grinders built by a number of other well-known manufacturers. Whatever the brand, GCH follows the strict remanufacturing guidelines detailed above.

Speak with one of our experienced sales engineers