Motorized Spindles Buying Guide: Ensuring Performance & Precision

In high-precision manufacturing, your machine is only as good as its spindle. It is the heart of the operation, dictating the speed, accuracy, and quality of every cut. Even a minor drop in spindle rigidity can lead to a significant increase in scrap rates, turning a profitable run into a costly waste of materials.

To maintain tight tolerances and high production schedules, understanding the role of motorized spindles for grinding machine applications is essential. When these components fail or degrade, accuracy suffers, and downtime spikes. However, sourcing the right replacements—whether full spindle assemblies or individual components—can restore your equipment to OEM specifications or better. This guide explores what to look for when selecting motorized spindles and how GCH Tool Group stands out as a reliable partner for your grinder replacement parts.

Understanding Motorized Spindles and Why They Are Critical

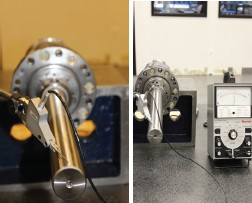

A motorized spindle, often called an integral or built-in motor spindle, combines the motor, spindle shaft, and tooling interface into a single, compact unit. Unlike belt-driven systems, the motor is directly integrated into the spindle housing. This design eliminates power transmission losses and reduces vibration, making it ideal for high-speed, high-precision applications.

You will typically find a motorized spindle for surface and cylindrical grinders, as well as tool grinders, where consistent torque and exceptional surface finish are non-negotiable. Because they operate at higher speeds and offer better dynamic balance, they are often the preferred choice for modern CNC grinding operations.

Key Benefits of Updating Motorized Spindles

Investing in grinding upgrades by replacing or remanufacturing your spindle offers immediate operational advantages:

- Better Precision: Integrated designs reduce vibration, leading to superior part geometry.

- Higher Speed Capability: Motorized units can achieve higher RPMs compared to belt-driven alternatives.

- Lower Maintenance: Fewer moving parts (no belts or pulleys) mean fewer items to wear out.

- Improved Dynamics: Faster acceleration and deceleration times improve overall cycle efficiency.

Common Signs You Need a Motorized Spindle Replacement

Spindle failure rarely happens overnight. Usually, the machine gives warnings that operators should monitor closely. Recognizing the signs that motorized spindle failure is imminent can save you from catastrophic downtime. Look for:

- Increased Vibration and Noise: Unusual humming or grinding sounds often indicate bearing failure or imbalance.

- Declining Surface Finish: Chatter marks or poor dimensional accuracy on the workpiece.

- Overheating: Excessive heat near the spindle nose suggests cooling system failure or friction issues.

- Inconsistent Speed: If the spindle struggles to hold RPM under load, the motor or drive may be compromised.

When these symptoms appear, a motorized spindle replacement or professional remanufacture is usually required immediately.

Motorized Spindle Buying Guide: Key Product Factors to Consider

Selecting the right replacement isn’t just about matching part numbers; it is about ensuring the component fits your specific application requirements. Here is what to consider when seeking to buy the right motorized spindle for your grinder:

Speed, Torque, & Load Capacity

The RPM and torque must align with your grinding application. High-speed grinding requires a spindle designed for rapid rotation, while heavy stock removal requires higher torque. Prioritize performance consistency over maximum speed alone.

Machine & Application Compatibility

When buying motorized spindles for grinders, verify the fit with your specific machine brand and model. Whether you operate a Blanchard, Cincinnati, or Okuma grinder, the interface must be exact to ensure safety and functionality.

Cooling, Lubrication, & Balance

Proper cooling and lubrication are vital for longevity. Ensure the spindle supports your machine’s coolant system. Furthermore, balance quality is critical; a spindle balanced to tight tolerances will minimize vibration and extend tool life.

Precision Manufacturing & Quality Control

The difference between a functional spindle and a high-performance one lies in manufacturing tolerances. A trusted supplier, like GCH Tool Group, adheres to strict quality assurance programs, testing final assemblies on stands designed to simulate actual operation.

Beyond the Spindle: Essential Grinder Replacement Components

A new spindle cannot fix a machine with other worn-out parts. To get the most out of your investment, inspect other grinder replacement components:

- Dressers and Dressing Tools: Worn dressers lead to poor wheel condition and finish.

- Workrest Blades: Essential for centerless grinding accuracy.

- Ball Screws and Slides: Ensure smooth motion control.

- Lubrication System: Protects the new spindle from premature wear.

Smart Tips for Buying Grinder Replacement Parts

When it comes to maintaining peak performance in your grinding operations, replacing a spindle is just one piece of the puzzle. Ensuring your machine operates at its best requires a holistic approach to component selection and maintenance. By focusing on the quality and compatibility of all grinder replacement parts, you can maximize uptime and extend the life of your equipment. Here are some practical tips to guide your purchasing decisions:

- Choose Experienced Suppliers: Work with specialists who understand grinding applications, not just general parts catalogs.

- Verify Specifications: Double-check dimensions, voltage, and taper sizes.

- Prioritize Quality: Look for grinder parts and components that meet or exceed OEM specifications.

- Look for Technical Support: A supplier should offer engineering advice, not just sales.

- Ensure Availability: Check the supplier’s inventory levels to ensure parts can be shipped immediately when needed.

The GCH Tool Group Advantage: Why Sourcing Matters

GCH Tool Group is the world’s largest supplier of new grinder spare parts, stocking over 10,000 items. When sourcing grinder accessories or critical spindles, we offer distinct advantages:

- “No Downtime” Philosophy: GCH Tool Group understands that stopped machines cost money.

- Remanufacturing Exchange Program: If a component fails, GCH Tool Group can ship a replacement unit immediately. You install the replacement and send the damaged unit back for credit, eliminating wait times for repairs.

- Technical Support: With experienced sales engineers and a team that serves customers in over 60 countries, you get expert guidance on every purchase.

Invest in Uptime with the Right Motorized Spindle

Selecting the right motorized spindles and components is not an expense—it is an investment in your machine’s uptime and your product’s quality. By understanding the signs of failure and knowing what to look for in a replacement, you can ensure long-term accuracy and ROI.

Whether you need a new unit or a remanufactured solution, GCH Tool Group provides the expertise and inventory to keep your operations running smoothly. Find the right solution for your facility using this motorized spindle buying guide and expert support from GCH Tool Group.