Place one call and access our extensive inventory of 10,000 new parts and components for all grinder types and brands

Get the Grinder Parts and Components You Need

Heald Grinder Replacement Parts and Components

GCH offers the world’s largest inventory of new mechanical and electrical spare parts for Heald ID grinding machines, including red head spindles and other component assemblies.

Each day of the week, GCH Tool Group receives Heald red head spindles in varying conditions of disrepair. Whether sent to us for evaluation or clearly in need of a complete remanufacture, GCH has a trusted process in place to remanufacture your Heald red head spindle in a timely and economical matter. Your expertly repaired spindle comes with a one-year new warranty.

Our exclusive exchange program allows GCH to send you a remanufactued component assembly to keep production running. Once you receive the remanufactured component you simply ship us the old one back.

Heald Spindles and Component Assemblies

All component assemblies, including belt-driven and high-frequency Heald red head spindles, dressers, feedboxes, X- and Z-axis slide assemblies, workheads and more, carry a new warranty and are offered on exchange, which saves you money and eliminates downtime.

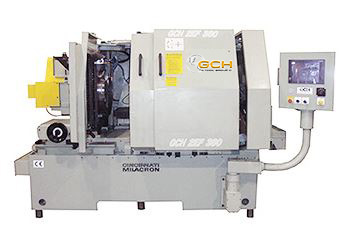

All new spare grinder parts and component assemblies for Heald models 161, 261, 271, 272, 273-A, 274, 361, 72-A, 74, 1CF70, 1CF80, 1CF90, 2CF70, 2CF90, Cinternal models 2EF700G and 2EF750G and others, are manufactured to OEM specifications. To make ordering easy, our state-of-the-art computerized inventory system categorizes all spares and assemblies with the same Heald part numbers found in your service and repair parts manual.

GCH also can retrofit your grinder controls from an older Cincinnati Milacron Heald or cross-slide system to a Fanuc, Allen Bradley or Siemens controls package (dependent upon the application). GCH eliminates downtime by engineering, building and testing the entire new control system on our floor before shipping it to your facility. No need to ship your grinder to us. Once the controls reach your plant, GCH technicians will install and debug the new system and train your operators.

Heald Grinder Upgrades, Service and Repair

GCH Tool Group also offers upgrades, accessories, tooling and service for your Heald grinder.

With over 30 years of experience in spindle and grinder repair, you can trust GCH to repair the most intricate components.

Speak with one of our experienced sales engineers