Place one call and access our extensive inventory of 10,000 new parts and components for all grinder types and brands

Get the Grinder Parts and Components You Need

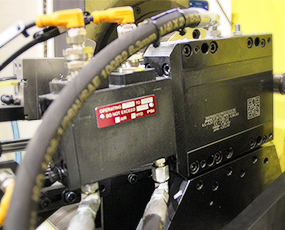

Steady Rests

GCH Tool Group supplies a full complement of steady rests for your ID and OD grinders.

Grinding parts that are long in comparison to their diameter often results in a number of challenges, including deflection at the point of contact.

This is a particular issue when grinding long tubes (ID), camshafts, crankshafts and other relative geometries, as well as axles and similar parts used in automotive or heavy equipment applications. The use of a steady rest is essential for accurately and precisely grinding these cylindrical workpieces.

Regardless of part diameter or length, our steady rests offer a wide range of benefits. The rests provide the necessary support to overcome deflection and ensure a proper finish. They increase the precision and uniformity of your grinding operation. Centering accuracy also improves, boosting overall part quality.

Key features of GCH steady rests include:

- Compatibility when retracting in-process gaging (IPG)

- Modular regrindable carbide or relappable PCD work rest pads

- Suitability for all crankshaft, camshaft and cylindrical grinding applications

- Three-point finely adjustable centering capability, resulting in high accuracy

GCH Tool offers steady rests for a wide variety of ID and OD grinders, including Heald, Toyoda, Okuma, Cincinnati, Landis and Norton.

Ordering steady rests from GCH is easy. Simply provide us with the make and model of your ID or OD grinder along with the part diameter, and our grinder experts will select the correct steady rest for your application.

Speak with one of our experienced sales engineers