Place one call and access our extensive inventory of 10,000 new parts and components for all grinder types and brands

Get the Grinder Parts and Components You Need

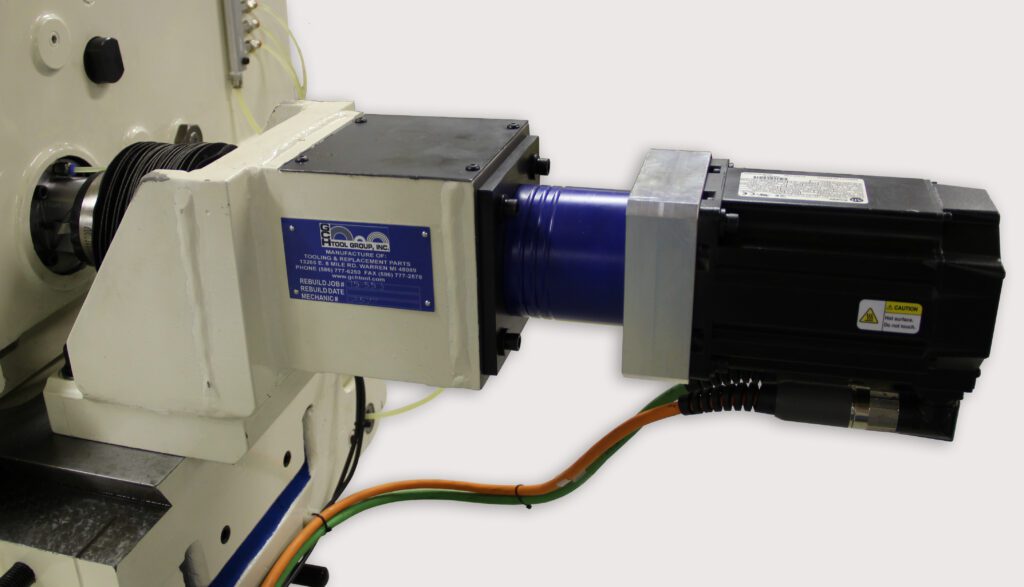

Servo Infeed System

GCH’s exclusive state-of-the-art digital servo infeed system replaces complex and troublesome Cincinnati mechanical hydraulic infeeds. Standard, off-the-shelf brackets allow GCH to directly couple the servo system to the ball screw, eliminating backlash found in gear-reduced servo infeed systems.

Benefits of Servo Infeed System:

- Eliminates costly set-up time and maintenance

Six Reasons to Add a Servo Infeed System to Your Grinder

- Improves accuracy: Every adjustment is 100% accurate

- Improves precision: Infeed assembly is more rigid which results in more uniform part size

- Improves throughput: Operator spends more time running the machine and less time making adjustments

- Improves SPC: SPC will be greatly enhanced, indicating a more stable and reliable process

- Cuts setup time: Adjustments no longer dependent upon the skill of the operator or a pricey dial indicator

Speak with one of our experienced sales engineers