The Hidden Costs of Counterfeit Centerless Grinder Parts

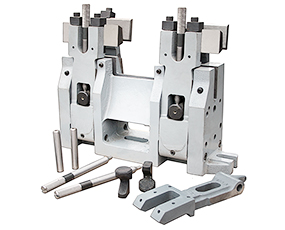

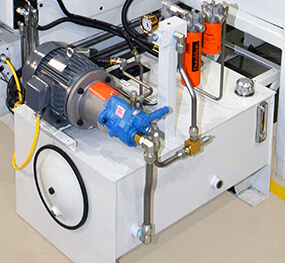

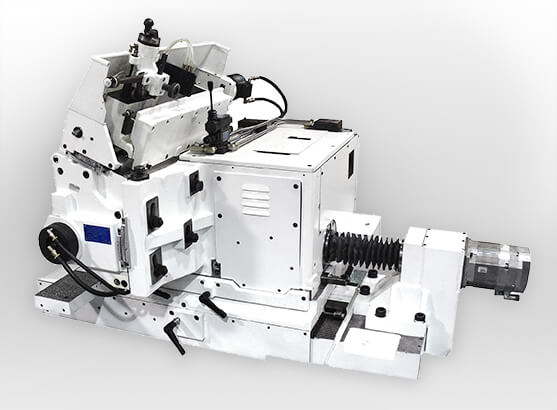

In precision machining, the performance of your equipment hinges on the quality of its components. Centerless grinder parts make up the heart of these machines, so their reliability is non-negotiable for achieving tight tolerances and superior finishes. However, there’s a growing problem threatening the integrity of grinding operations: the influx of counterfeit and substandard replacement … The Hidden Costs of Counterfeit Centerless Grinder Parts