The Role of Hydraulic Assemblies in Centerless Grinding

Centerless grinding is an indispensable machining process that ensures high-quality surface finishes. Central to this discipline is the hydraulic assembly—a silent yet powerful force behind this mechanical refinement. These assemblies enable the firm yet gentle handling of workpieces and the smooth operation of servo infeed systems. It’s these hydraulic components that convert raw power into precise movements, enabling the creation of parts that are accurate, functional and durable.

In this blog post, we’ll dive deep into how these assemblies work and their importance for improving process efficiency, product quality and cost savings.

Understanding Hydraulic Assemblies and Their Function

What Is a Hydraulic Assembly?

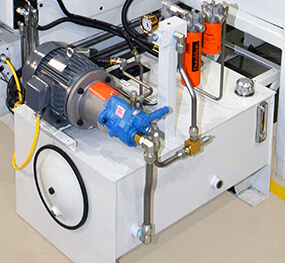

A hydraulic assembly in centerless grinding is a network of interconnected components that utilizes pressurized fluid to power various machine functions. This typically includes:

- Oil Reservoirs: These are the lifeblood chambers of the assembly, storing the hydraulic fluid needed to power the machinery.

- Pumps: They are the muscular force that generates the pressurized flow of oil to essential machine parts.

- Valves: Think of them as the gatekeepers, ensuring the precise regulation and direction of the hydraulic flow.

- Filters: They’re the system’s lungs, ensuring that the oil that nourishes the machinery is clean and free from contaminants.

- Actuators: The limbs of the assembly, these convert hydraulic pressure into mechanical motion, controlling actions like wheel feeds and work piece holding.

How Does It Work in Centerless Grinding?

In the realm of centerless grinding, these assemblies apply mechanical hydraulic infeed to orchestrate a precision dance. The regulated flow, pressure and direction of hydraulic fluid power essential movements such as:

- Regulating Wheel Control: Ensuring the correct linear feed of the workpiece into the grinder.

- Grinding Wheel Encounters: Controlling the force and feed rates against the workpiece for seamless material removal.

- Blade System Adjustments: Managing the position of the blade to accommodate various workpiece diameters.

- Workrest Stabilizers: Helping to maintain the workpiece position and balance during grinding.

Benefits of Utilizing Hydraulic Assemblies

GCH Tool Group’s website highlights several advantages of incorporating hydraulic assemblies in centerless grinding operations:

- Improved Thermal Stability: Hydraulic assemblies divert excess heat generated during grinding away from the machine bed. This maintains a cooler operating temperature, reducing thermal distortion and ensuring consistent part quality.

- Enhanced Oil Filtration and Lifespan: The closed-loop system of a hydraulic assembly keeps the oil cleaner for extended periods. This reduces wear and tear on machine components and minimizes the need for frequent oil changes, leading to cost savings.

- Reduced Contamination Risks: By isolating the hydraulic oil from the grinding process, swarf (metal shavings) and water are prevented from entering the system. This safeguards the spindle from premature wear and potential failure.

- Addressing Obsolete Equipment: In instances where older grinders rely on pumps that are no longer manufactured, hydraulic assemblies offer a modern solution. They provide a reliable and efficient replacement for outdated components.

Optimizing Centerless Grinding with GCH Tool Group’s Hydraulic Assemblies

GCH Tool Group offers high-quality hydraulic assemblies specifically designed to enhance the performance of centerless grinders. Here’s how our solutions can benefit your operations:

- Compatibility: GCH Tool Group’s assemblies are compatible with a wide range of centerless grinders.

- Performance: Our systems are engineered to deliver optimal flow rates and pressure, ensuring efficient machine operation.

- Durability: Components are manufactured using robust materials to withstand the demanding environment of a grinding workshop.

- Expertise: The GCH Tool Group team possesses in-depth knowledge of centerless grinding applications and can provide expert advice on selecting and implementing the most suitable hydraulic assembly for your specific needs.

Enhance Accuracy in Centerless Grinding with GCH Tool’s Hydraulic Assemblies

In the world of precision grinding, hydraulic assemblies are the unsung heroes, ensuring that centerless grinders operate at their best and deliver results with unmatched precision. From enhancing the final finish to safeguarding against potential breakdowns, their influence touches every facet of the operation.

By partnering with GCH Tool Group and adopting our cutting-edge hydraulic solutions, businesses are evolving their operational machinery while infusing a spirit of reliability, longevity and style into their manufacturing ethos.

Our team of sales and engineering experts is highly experienced in centerless, internal, surface and CNC grinding. Contact us today for more information on how you can redefine your grinding establishment with hydraulic assemblies and other high-quality grinder parts and components.