In-House vs. Specialist: Why Outsourcing Your Precision Grinding Spindle Rebuild Is the Smart Choice

The spindle is the heart of every precision grinder. Its condition determines grinding performance, surface finish accuracy, and overall part quality. When a spindle begins to wear, the consequences are immediate and costly: runout increases, surface finishes deteriorate, and scrap rates climb.

Faced with a failing spindle, manufacturers must decide: rebuild in-house or outsource to specialists?

Many operations assume that handling the work internally saves money and reduces turnaround time. In reality, in-house precision grinding spindle rebuilds often lead to inconsistent results, extended downtime, and premature failures.

GCH Tool Group doesn’t just repair spindles—we rebuild them to like-new or better condition, delivering OEM-equivalent or improved performance specifications. Here’s why partnering with experts makes all the difference.

Why In-House Precision Grinding Spindle Rebuilds Often Fail

Because most maintenance teams lack the equipment, training, and resources needed to perform reliable spindle rebuild, what starts as a cost-saving measure quickly becomes a cycle of trial and error. Let’s look at the most common reasons why in-house rebuilding falls short.

Lack of Proper Balancing & Vibration Analysis Equipment

Spindle balance directly affects grinder performance. Even minor imbalances at operating speeds can cause vibration, premature bearing wear, and poor surface finishes. Most in-house teams don’t have precision dynamic balancing machines or vibration diagnostic systems capable of analyzing imbalance at these speeds (ranging from 5,000 to 60,000 RPM, depending on grinder type). Without them, rebuilds rely on guesswork, leading to inconsistent results and repeated failures.

Inconsistent Assembly Techniques & Bearing Preload Issues

Improper bearing preload, incorrect torque settings, or contamination during assembly can destroy precision bearings in a matter of hours. In-house rebuilds often lack the controlled environments and documented procedures necessary to prevent these errors. The result is reduced spindle life, unexpected downtime, and lost productivity.

Limited Access to OEM-Spec Replacement Parts

In-house rebuilds frequently rely on generic or mismatched components that compromise spindle integrity. Using verified OEM or precision-engineered equivalent parts ensures proper fit, alignment, and long-term reliability. Without access to precision grinder parts, in-house teams unknowingly introduce weaknesses that lead to early failure.

Small Alignment Errors, Big Consequences

Even a tiny misalignment during spindle reassembly can cause tool deflection or spindle runout. The consequences include tolerance drift, chatter, poor part quality, increased scrap, and shortened spindle lifespan. Precision assembly requires specialized fixturing, measuring equipment, and training—resources most in-house teams simply don’t have.

Precision Grinding Spindle Rebuild: What the Process Involves

A true precision grinding spindle rebuild follows a rigorous, step-by-step process designed to restore OEM-level performance. Here’s what it entails:

Intake & Diagnostics

The rebuild process begins with a comprehensive evaluation. Technicians document the spindle’s condition, identify failure modes, and determine the root cause of the problem.

Detailed Inspection & Metrology

Each component is chemically cleaned and geometrically inspected. Advanced metrology tools detect flaws as small as half a micron (0.00002 inch). Encoder testing verifies feedback accuracy, ensuring the spindle can meet the precision demands of modern grinding operations.

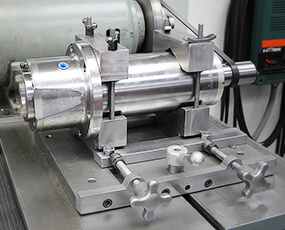

Precision Grinding & Machining

All housing bores, shaft journals, shoulders, and faces are restored to better-than-OEM tolerances. This step eliminates wear, corrects misalignments, and prepares the spindle for reassembly.

Grinder Replacement Parts (OEM-Quality)

Worn or damaged components are replaced with verified OEM or precision-engineered equivalents. This ensures proper fit and alignment and long-term reliability.

Dynamic Balancing & Vibration Correction

Spindles are dynamically balanced using specialized equipment. Vibration analysis confirms that the spindle operates smoothly at all speeds, eliminating chatter and extending bearing life.

Controlled Reassembly with Proper Bearing Preload

Reassembly takes place in a cleanroom environment to prevent contamination. Bearing preload is applied according to precise specifications, ensuring optimal performance and longevity.

Dynamic Testing & Validation

After assembly, each spindle runs for a minimum of eight hours on specially designed test stands. Quality tests are performed at various temperatures and speeds to confirm that the spindle meets or exceeds OEM specifications.

Documentation & Handover

Every remanufactured spindle comes with a detailed test report and balance analysis. This documentation provides peace of mind and serves as a reference for future maintenance.

In-House vs. Outsourced: The Real Cost Comparison

It’s a common misconception that in-house vs. outsourced spindle repair favors the former on cost. While in-house rebuilds may seem cheaper upfront, they often result in higher long-term expenses due to poor accuracy, premature failures, and unplanned downtime.

In-House Rebuild Challenges

Performing an in-house precision grinding spindle rebuild has some very specific challenges:

- Trial-and-Error Repairs: Without proper diagnostic tools, in-house teams often attempt multiple fixes before resolving the issue. Each attempt costs time and money, with no guarantee of success.

- Extended Downtime: In-house rebuilds typically take longer due to limited resources and competing priorities. Production schedules suffer, and the cost of lost throughput quickly exceeds any perceived savings.

- Uncertain Results: Without dynamic testing and validation, there’s no way to confirm that the spindle will perform as expected. Many in-house rebuilds fail within weeks or months, requiring additional repairs or complete replacement.

- Hidden Costs: Beyond labor and parts, in-house rebuilds incur hidden costs: increased scrap, rework, machine wear, and operator frustration. These add up over time, eroding profitability.

Outsourced Rebuild Advantages

Outsourcing a spindle rebuild has some very distinct advantages:

- Guaranteed Precision: A specialist provider like GCH Tool Group deliver spindles restored to OEM or better specifications. Every rebuild is tested, validated, and documented.

- Quicker Turnaround: With dedicated facilities and experienced technicians, outsourced rebuilds are completed faster. To eliminate downtime entirely, GCH offers spindles through our exclusive Remanufacturing Exchange Program.

- Extended Spindle Life: Proper rebuilds using OEM-quality components and precision assembly techniques significantly extend spindle lifespan, reducing the frequency of future repairs.

- Consistent Quality Assurance: Every spindle undergoes rigorous inspection, balancing, and testing. The result is a predictable, reliable performance that keeps production on track.

Why GCH Tool Group Excels at Precision Grinding Spindle Rebuilds

GCH Tool Group has over 50 years of experience providing grinder spindle replacement parts and rebuilding services to major industries, including aerospace, automotive, bearing, and medical manufacturing. Our dedicated rebuild facilities house advanced diagnostic systems, precision measuring tools, and state-of-the-art balancing equipment.

What sets GCH apart:

- Factory-Trained Technicians: Our team has the expertise to rebuild spindles for all major grinder brands, including Cincinnati Milacron, Landis, and Norton.

- Access to OEM-Quality Spindle Parts & Components: With an extensive inventory of over 10,000 new grinder parts and components, we ensure every rebuild uses the right parts for optimal performance.

- Cleanroom Assembly: Reassembly takes place in a 10,000-class cleanroom to maintain bearing and component integrity, preventing contamination that can lead to premature failure.

- Rigorous Dynamic Testing: Every spindle runs on specially designed test stands for a minimum of eight hours. We perform vibration analysis, balance verification, and performance testing at various speeds and temperatures to confirm OEM-level accuracy.

Restore OEM Precision with Expert Spindle Rebuilds

Outsourcing your precision grinding spindle rebuild to GCH Tool Group ensures OEM-level accuracy, extended spindle life, and peace of mind. When you choose a specialist over an in-house approach, you’re investing in performance, reliability, and long-term profitability.

GCH Tool Group is your one-stop partner for precision grinder maintenance, spindle rebuilding, and tooling upgrades. We don’t just fix problems—we deliver long-term solutions that improve grinder performance and reduce total cost of ownership.

Restore OEM precision—partner with GCH Tool Group for expert spindle rebuilds. Contact us today to learn more about GCH’s grinder parts and solutions.