Cincinnati Grinder Ball Screw Accuracy: A Complete Guide

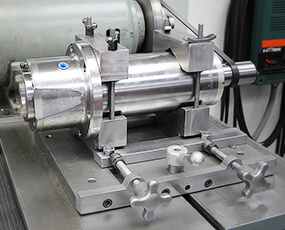

Ball screws are the backbone of precision grinding. They convert rotary motion into linear motion, enabling Cincinnati Milacron grinders to position workpieces with micron-level accuracy. By translating rotary motion into highly controlled linear movement, ball screws directly influence positioning accuracy and repeatability within the machine’s motion system. When these components degrade, the effects ripple through … Cincinnati Grinder Ball Screw Accuracy: A Complete Guide

Ball screws are the backbone of precision grinding. They convert rotary motion into linear motion, enabling Cincinnati Milacron grinders to position workpieces with micron-level accuracy. By translating rotary motion into highly controlled linear movement, ball screws directly influence positioning accuracy and repeatability within the machine’s motion system. When these components degrade, the effects ripple through … Cincinnati Grinder Ball Screw Accuracy: A Complete Guide