How Precision Tailstocks Improve Accuracy in Grinding Machines

Many legacy grinding machines are built to last, often performing reliably for decades. However, even the sturdiest machine is only as precise as its components. In many manufacturing environments, the tailstock for grinding machines (and its internal components) is the overlooked culprit behind production errors. Over time, tailstock limitations—such as component wear, misalignment, vibration, vibration, and worn quills—begin to restrict overall accuracy.

To maintain tight tolerances in modern manufacturing, relying on aged tailstock components is a liability. A high-precision tailstock is essential for maintaining stability, ensuring accuracy, and maximizing productivity, especially when dealing with demanding machining environments and complex workpieces.

How the Tailstock Supports Long, Slender, & Heavy Workpieces

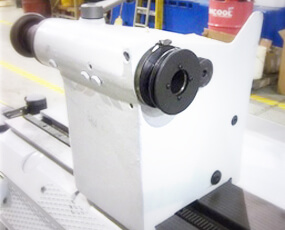

The primary function of the tailstock is to support the free end of the workpiece. This role becomes critical when grinding long, slender, or heavy parts. The integrity of the grinding process relies heavily on maintaining perfect alignment between the headstock and the tailstock.

If the tailstock assembly or its internal components—such as the quill, bearings, or center—lack rigidity or precision, the workpiece can deflect under grinding forces. This deflection directly impacts dimensional accuracy and surface finish quality. Furthermore, a stable tailstock reduces the load on the headstock and spindle, effectively extending tool and spindle life. As machines age and production tolerances tighten, the need for rigidity in grinder components becomes increasingly critical to avoid costly scrap.

Common Tailstock Problems in Older Grinding Machines

While older grinding machines are often mechanically sound, their original tailstock components may no longer meet today’s production requirements. Tailstock solutions for older machines are frequently necessary because original components wear over time and no longer deliver consistent performance.

Common problems include excessive play and quill wear, which introduce unpredictability into the grinding cycle. Alignment drift is another frequent issue, causing tapered parts that fail quality control. Additionally, manually fed tailstocks rely heavily on operator adjustments, leading to support pressure inconsistencies. Without the rigidity required for modern cutting speeds, these older units are susceptible to increased vibration and chatter, compromising the final finish.

Signs Your Machine Requires a High-Precision Tailstock

Identifying when a tailstock has become a liability is the first step toward restoring machine performance. If your facility is experiencing frequent part rejections or struggling with dimensional inaccuracies, the tailstock is a likely suspect.

Visible taper, poor concentricity, and excessive runout at the workpiece are clear indicators of tailstock accuracy failure. Operators may also notice that setup times are increasing as they struggle to compensate for machine errors with manual adjustments. If your team is unable to meet current production tolerances or if downtime costs are growing, finding a reliable tailstock vibration issues solution through a high-precision upgrade is imperative.

Types of Tailstocks for Modern Machining Needs

Upgrading doesn’t always mean replacing the entire machine. There are various industrial grinder tailstock solutions available to suit different production volumes and precision requirements.

Manual Tailstocks

Manual tailstocks are typically suitable for basic applications and lower production volumes. While cost-effective, manual feed systems depend heavily on operator skill to achieve consistent pressure and alignment, which can introduce variability over time.

Hydraulic Tailstocks

For operations involving long or heavy workpieces, hydraulic tailstocks offer a significant advantage. Hydraulic quill actuation provides consistent support pressure, improving stability and reducing the risk of part deflection during the grinding process.

CNC / Servo-Controlled Tailstocks

In modern automated environments, CNC or servo-controlled tailstocks are the gold standard. These systems allow controlled quill positioning and consistent actuation pressure, making them well suited for modern CNC grinding applications where repeatability is critical.

Precision Quill & Center Configurations

Regardless of actuation method, the quill and center play a critical role in tailstock performance. Tailstocks for precision machining applications require hardened, ground quills for durability, along with properly selected live or dead centers matched to the specific workpiece and grinder configuration.

Key Benefits of Using a High-Precision Tailstock

Investing in a high precision tailstock offers a high return on investment by revitalizing existing equipment. It serves as a cost-effective alternative to complete machine replacement, allowing manufacturers to get more out of their current assets.

The immediate benefits include improved accuracy and stability, which translate directly to better surface finish and part quality. By reducing vibration and deflection, these upgrades also extend machine life and productivity. Ultimately, a precision upgrade enables older machines to meet modern production demands without the capital expense of buying new equipment.

How GCH Tool Group Delivers Reliable Tailstock Solutions

When it comes to sourcing reliable grinder parts and upgrading a tailstock for grinding machines, GCH Tool Group stands out as an industry leader. With proven experience in upgrading and remanufacturing components, we take an application-driven engineering approach to every project.

GCH Tool Group provides remanufactured tailstock assemblies and custom tailstock solutions in the form of custom-built replacement components manufactured to OEM specifications, supporting a wide range of machine brands including Cincinnati, Landis, and Norton. The focus is always on rigidity, accuracy, and long-term performance. From initial evaluation through final installation support, GCH Tool Group offers end-to-end solutions that restore tailstock performance and reliability.

Restoring Precision to Your Operations

The tailstock is not merely a support mechanism; it is a critical variable in the equation of grinding accuracy. A worn or inadequate tailstock inevitably leads to alignment drift, poor surface finishes, and wasted materials. By upgrading to a high-precision tailstock, manufacturers can eliminate these variables, ensuring consistent quality and extending the lifespan of their grinding machinery.

GCH Tool Group is a trusted supplier of high-precision tailstock components and remanufactured assemblies, delivering application-driven solutions that help manufacturers optimize grinding performance.

Contact us today to explore precision tailstock solutions engineered to restore accuracy and reliability to your grinding operations.