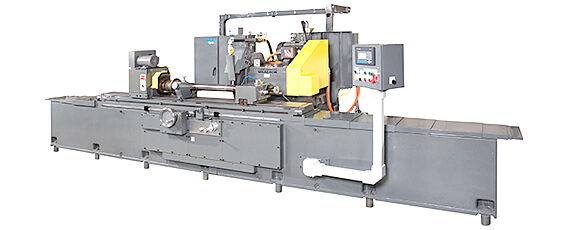

How Precision Tailstocks Improve Accuracy in Grinding Machines

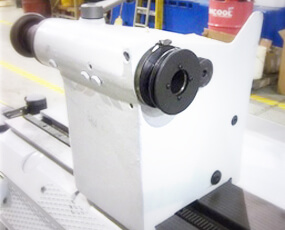

Many legacy grinding machines are built to last, often performing reliably for decades. However, even the sturdiest machine is only as precise as its components. In many manufacturing environments, the tailstock for grinding machines (and its internal components) is the overlooked culprit behind production errors. Over time, tailstock limitations—such as component wear, misalignment, vibration, vibration, … How Precision Tailstocks Improve Accuracy in Grinding Machines