Place one call and access our extensive inventory of 10,000 new parts and components for all grinder types and brands

Get the Grinder Parts and Components You Need

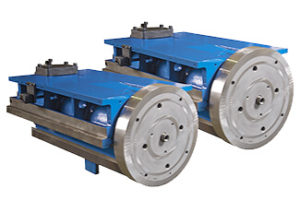

Understanding the Cost Behind Grinder Spindle Repairs

When your grinding operations grind to a halt due to a faulty spindle, immediate action is necessary. However, for facility managers and business owners, the decision often comes down to the numbers. Understanding the true cost to repair a grinder spindle involves more than just looking at a price tag. It requires analyzing the long-term value, the precision restored, and the downtime prevented.

At GCH Tool Group, a high-quality repair does not just patch a problem; it restores your equipment to OEM specifications—or better. While initial costs vary, investing in a professional industrial spindle repair service ensures your manufacturing unit maintains peak efficiency without the massive capital expenditure of purchasing a new machine.

What Determines the Cost to Repair a Grinder Spindle?

Every spindle is unique, and so is every failure. The final quote for a repair depends on several critical variables that influence the scope of work required.

Damage Level

The extent of the wear or damage is the primary cost driver. A spindle that simply needs new seals and a cleanup will cost significantly less than one requiring a complete shaft rebuild or extensive chroming and grinding work due to a crash.

Spindle Type

Different grinding machines use different spindle technologies. A simple belt-driven spindle generally costs less to repair than a complex high-frequency motorized spindle with integrated sensors and cooling systems.

Parts & Materials

The cost of replacement grinder parts fluctuates based on availability and quality. High-precision ceramic bearings, for example, command a higher price than standard steel bearings but offer superior performance and longevity.

Precision Standards

Achieving micron-level tolerances requires specialized equipment and time. The tighter the tolerance required for your specific application, the more rigorous the testing and balancing process will be, which can influence the final cost.

Labor & Expertise

Skilled technicians are essential for a successful rebuild. The labor cost reflects the expertise required to disassemble, diagnose, and rebuild complex assemblies without causing further damage.

GCH Tool Group Grinder Spindle Repair Pricing & Service Inclusions

At GCH Tool Group, we believe in transparency. While exact pricing requires a thorough evaluation of your specific unit, we categorize repairs to help you anticipate costs.

- Minor Rebuilds: Typically involve cleaning, seal replacement, and minor adjustments. These are the most affordable option.

- Moderate Rebuilds: Include bearing replacement and minor machining of components.

- Full Spindle Rebuilds: Involve extensive machining, shaft restoration, motor rewinding (if applicable), and full component replacement.

Our comprehensive service includes:

- Complete disassembly and meticulous cleaning

- Detailed failure analysis

- Replacement of bearings with high-grade precision equivalents

- Dynamic balancing to reduce vibration

- Clean room reassembly

- Rigorous runoff testing at operating speeds

- Warranty: We stand behind our work with a solid warranty on parts and labor.

For more about our services, visit our spindle repair and rebuild page. Or reach out today for a quote on your specific needs.

How GCH Tool Group Can Help You Save on Grinder Spindle Repairs

A cost-effective spindle rebuild isn’t just about the lowest upfront price; it’s about lifespan. GCH Tool Group helps you save by extending the life of your current assets. By using better-than-OEM components and modernizing older designs, we ensure your repaired spindle lasts longer than the original. Additionally, our grinder accessories and parts inventory allows us to source components quickly and affordably, passing those savings directly to you.

Why Choose GCH Tool Group for Grinder Spindle Repair Services?

Choosing GCH Tool Group means partnering with industry leaders who understand the nuances of grinder spindles. We don’t just swap parts; we engineer solutions. Our facility is equipped with state-of-the-art testing equipment, ensuring that every spindle we return performs at maximum capacity. GCH Tool Group offers quick turnaround times to minimize your downtime and provide support for nearly every major grinder brand in the industry.

Grinder Spindle Repair: FAQs

How long does it take to repair a grinder spindle?

Standard repairs are typically completed within a few weeks, but GCH Tool Group has expedited services available for emergency situations. The timeline depends heavily on the complexity of the damage and parts availability.

Repair vs. replace: Which is more cost-efficient?

In most cases, repairing a spindle is 40% to 60% less expensive than buying a new one. Repairing also often leads to faster turnaround times compared to the long lead times for new OEM spindles.

Can my old or discontinued grinder spindle still be repaired?

Yes, GCH Tool Group specializes in supporting legacy equipment. If standard grinder parts are no longer available, we can often remanufacture or reverse-engineer the necessary components.

Does GCH Tool Group offer a warranty on spindle repairs?

Absolutely. We provide a full warranty on all materials and workmanship, giving you peace of mind that your rebuilt spindle will perform reliably.

How can I get a quote for my grinder spindle repair?

Getting a quote is simple. Contact the GCH Tool Group team with your spindle model and a description of the issue. We will guide you through the evaluation process to provide an accurate estimate.

Speak with one of our experienced sales engineers