The Ultimate Checklist for Choosing the Right ID Grinder Replacement Parts

In precision manufacturing, your ID grinder is only as reliable as its weakest component. Selecting the right ID grinder replacement parts is a critical decision that directly impacts operational efficiency and product quality. Poor part selection can lead to costly downtime, inconsistent tolerances, heat issues, excessive vibration, and a shortened machine life.

Conversely, choosing high-quality, OEM-grade parts ensures your equipment operates at peak performance, maintaining accuracy and extending its service life. This seven-point checklist provides a systematic approach to choosing ID grinder replacement parts, ensuring you make an informed decision that benefits your bottom line.

1. Know Your Machine: Identify Make, Model, & Configuration

Before ordering any part, you must verify the exact specifications of your grinder. This includes its make, model, year of manufacture, and original build configuration. This information can typically be found in engineering documents, on serial tags, or within the machine schematics.

Matching the original specifications is crucial. It prevents common problems like alignment issues, tolerance errors, and misfitting spindles. A part that isn’t a perfect match can cause excessive wear on both the new component and the machine itself, leading to premature failure.

2. Evaluate Critical Grinding Performance Requirements

The performance demands of your application should guide your part selection. Consider your required tolerance ranges, target surface finishes, and typical production loads. You also need to evaluate the material being ground, noting its hardness, abrasiveness, and heat generation properties.

Higher-performance requirements, such as those for high-accuracy grinding parts, demand premium-grade replacement components. Settling for a lower-quality part in a high-demand application will inevitably lead to subpar results and increased scrap rates.

3. Diagnose the Root Problem

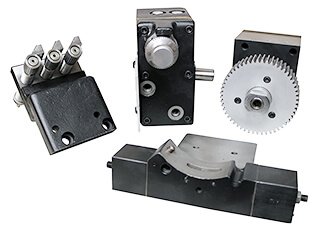

Before replacing a failed component, it’s essential to understand why it failed. Common failure points in ID grinders include:

- Spindles and bearings

- Workholding assemblies

- Dressing systems

- Feed mechanisms

- Lubrication and coolant delivery systems

Inspect the failed part to identify the true cause of the issue. Was it simple wear and tear, or was the failure caused by heat, contamination, misalignment, or a lack of lubrication? Diagnosing the root cause ensures you’re not just treating a symptom, which could lead to repeated failures.

4. Check Material & Build Specifications

The material grade and manufacturing quality of a replacement part have a direct effect on its performance. These factors influence grinding stability, heat resistance, durability, and precision.

When comparing OEM-grade ID grinder replacement parts to generic alternatives, consider the long-term implications. OEM-grade components are manufactured with correct metallurgical properties and to strict tolerances, which directly impacts the accuracy and lifespan of your ID grinder. A cheaper alternative might save money upfront but often costs more in the long run due to reduced performance and frequent replacements.

5. Confirm Dimensional & Tolerance Compatibility

Always verify the exact dimensional compatibility of any grinder replacement parts before ordering. This includes checking key dimensions like bore sizes, shaft diameters, and bearing fits, as well as alignment requirements.

Even minuscule dimensional deviations can have significant consequences, causing issues like spindle runout, loss of accuracy, vibration, and poor surface finishes. These problems can increase cycle times and lead to more frequent maintenance interventions, impacting overall productivity. This makes a comprehensive buying checklist for ID grinder parts an invaluable tool.

6. Consider Cost, Life, & Maintenance

When evaluating replacement parts, look beyond the initial purchase price. A holistic view of total cost of ownership should include factors like the component’s expected lifespan, its wear behavior, and whether it can be rebuilt.

High-quality parts often deliver greater long-term value by reducing wheel consumption, dressing frequency, and unplanned downtime. These benefits, combined with lower maintenance labor costs, contribute to a superior return on investment. Sometimes, grinding upgrades or retrofit solutions can offer even better performance and longevity than the original part.

7. Determine Availability & Lead Times

Production continuity depends on part availability. Compare the lead times for standard, off-the-shelf ID grinder parts and components with those for engineered or custom-built replacements. In high-production environments, it’s wise to stock critical spares to avoid costly emergency downtime. Planning ahead ensures that a part failure doesn’t halt your entire operation..

Why Choose OEM-Grade Parts from GCH Tool Group?

GCH Tool Group is a trusted partner for manufacturing units that rely on precision grinding. With an extensive inventory of over 10,000 new grinder parts and components, we help minimize downtime and ensure you get exactly what you need.

Here’s why businesses choose GCH Tool Group for their high-precision grinder parts:

- Precision-Built Parts: We supply components for major grinder brands like HEALD, Bryant, Nova, Okuma, and others, all built to meet or exceed OEM specifications.

- Custom Replacements: Our engineers can create custom solutions for legacy or unsupported machines.

- In-Stock Components: Our massive inventory means we can ship most parts immediately, reducing your downtime.

- Expert Support: We provide engineering support from selection through installation to ensure optimal performance.

- Lower Lifetime Costs: Our reliable, accurate parts improve your total cost of ownership.

Make the Right Choice for Your ID Grinder

Following this detailed checklist ensures you select the correct part for your ID grinder, maximizing machine accuracy and extending equipment life. Remember, choosing replacement parts is a technical decision, not just a transactional one. The right component will enhance your operations, while the wrong one can cause significant setbacks.

Need OEM-grade ID grinder replacement parts? Contact GCH Tool Group today.