Place one call and access our extensive inventory of 10,000 new parts and components for all grinder types and brands

Get the Grinder Parts and Components You Need

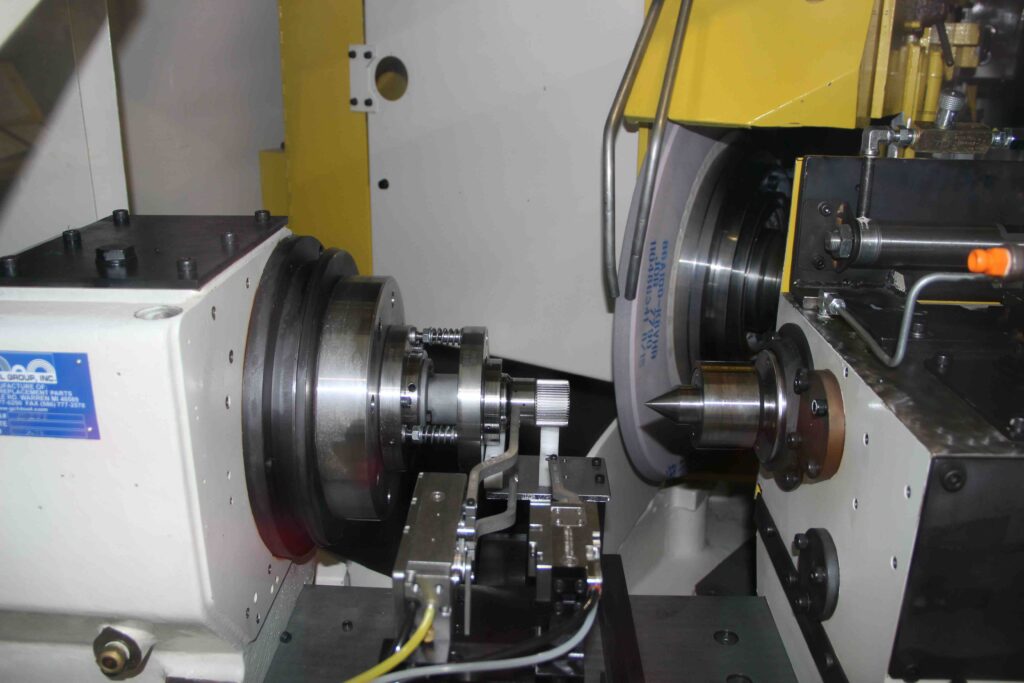

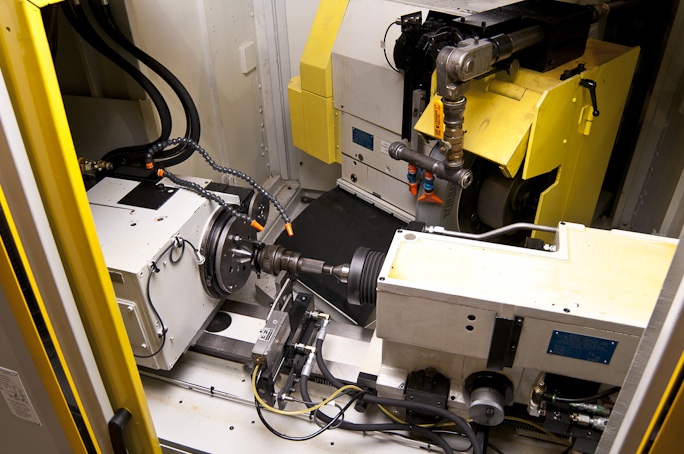

Grinding Machine Gaging Systems

Ever increasing quality standards mean that all your parts – every single one of them – must always be perfect. There’s no room for error in today’s fast-paced manufacturing environment, and even if there were, you don’t want to be the one responsible for a heap of bad and/or scrapped parts. Ensure that your parts meet your specs day in and day out by installing a post-process gage system on your grinder. Designed to dynamically measure workpieces and provide process control feedback (comp signals), this user-friendly gaging system will automatically measure each part, removing operator error, and ensure that your machine is working as it should.

Benefits Grinding Machine Gaging Systems

- Easy to install and setup

- Increase production quality

- Uniformity of inspection requirements

- Constant level of quality of production

- Reduce processing times

- Increase grinder productivity

Over the years, GCH Tool Group has successfully retrofit numerous centerless, ID, OD and double disc grinders with in process or post process gaging systems.

Used to ensure that customer parts fall well within desired tolerances, GCH proudly offers Marposs or Control Gaging systems, known for their reliability and accuracy.

Speak with one of our experienced sales engineers