The Double Disc Grinder Wear Zone: Pinpointing the 5 Components That Kill Precision

Double disc grinding delivers unmatched precision and productivity in manufacturing operations. When these machines run smoothly, they produce parts within tight tolerances while maintaining exceptional surface finishes. However, beneath the surface of consistent operation lies a hidden problem: specific double disc grinder components wear faster than others, quietly destroying accuracy and eating into your bottom line.

Understanding which components might fail first—and why—can mean the difference between maintaining peak performance and facing costly downtime. This deep dive examines the five most wear-prone components in your double disc grinder and reveals how genuine replacement parts can solve these critical issues, including key double disc grinder maintenance tips.

The Heart of the Machine: DDG Spindles & Bearings

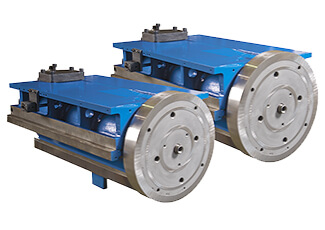

Grinding spindles form the foundation of precision in any double disc grinder. These critical components directly affect grinding performance and accuracy, making them prime candidates for wear-related failures.

The most common problems include excessive heat buildup, thermal drift, and chatter vibration. Over time, spindles can develop vibrations, become overheated, or produce inconsistent grinding results. These issues create a cascade effect: loss of parallelism between grinding wheels, poor surface finish, and, in a worst-case scenario, catastrophic spindle failure that brings production to a halt.

Signs of failing spindles include excessive noise, overheating, vibration, or inconsistent grinding quality. The solution involves monitoring vibration levels, using high-quality lubrication, and replacing worn units with OEM-grade spindles and bearings before complete failure occurs.

Feed System Fidelity: Feed Rolls, Belt Feeders & Guide Bars

Your grinder’s feed system controls how parts move through the grinding zone. When feed rolls, belt feeders, or guide bars wear down, they can cause inconsistent feed rates, part misalignment, and surface defects.

These problems manifest as part jamming, increased scrap rates, and missed size tolerances. A worn feed system can no longer deliver parts smoothly between the opposing grinding wheels, leading to uneven material removal and dimensional errors.

Regular maintenance and timely replacement of feed rolls and guide components prevent these issues. Quality double disc grinder replacement parts ensure consistent part flow and accurate positioning throughout the grinding cycle.

The Backbone: Ball Screws, Way Systems, & Hydraulic Cylinders

The structural components that control positioning and movement form your grinder’s backbone. Ball screws, way systems, and hydraulic cylinders work together to maintain precise positioning and smooth operation.

Problems arise when these components develop backlash, jerky movement, or non-repeatable positioning. The effects include inconsistent part thickness, taper formation, and complete loss of repeatability between grinding cycles.

Preventive lubrication and regular inspection help identify wear before it becomes critical. Replacing worn ball screws, ways, and hydraulic components with genuine parts restores smooth, accurate positioning and eliminates costly dimensional variations.

Power & Motion: Drive Motors & Gear Assemblies

Drive motors and gear assemblies provide the power and torque necessary for grinding operations. When these components fail, they create power loss, overheating, and irregular torque delivery.

These issues reduce grinding efficiency, slow cycle times, and create unbalanced loads on spindles. Compromised power delivery affects surface finish quality and can accelerate wear in other double disc grinder components.

Monitoring current draw and performing thermal checks help identify problems early. Replacing drive motors and gear assemblies before complete failure prevents secondary damage and maintains consistent grinding performance.

Control & Accuracy: Dressing Units & Alignment Systems

Grinding wheel dressers and alignment systems maintain wheel condition and ensure proper setup. Dresser tools remove worn abrasive grains and restore grinding wheels to optimal condition, ensuring consistent material removal rates and surface finishes.

Problems occur when dressing units wear out or alignment systems lose calibration. Poorly dressed wheels, misaligned guides, and inaccurate feed alignment result in rapid wheel wear, inconsistent finishes, and increased scrap rates.

If grinding wheels clog frequently, produce uneven grinding, or show deterioration in surface finish, dresser replacement becomes necessary. Routine calibration, precision alignment tools, and replacement dressers and guides maintain grinding accuracy.

How Wear in One Component Impacts the Whole Machine

Double disc grinder wear creates interconnected problems throughout your machine. Understanding these relationships helps prioritize maintenance and prevent cascade failures.

When spindle issues develop, they transfer vibration into the feed system, which can disrupt feed roll performance and cause parts to mis-track through the grind zone. Likewise, misaligned guides can accelerate wear in feed rolls or guide bars by creating uneven contact and inconsistent part pressure between grinding wheels.

These interconnected failures demonstrate why addressing component wear early prevents more extensive damage. A single worn component can trigger problems throughout the entire system, multiplying repair costs and extending downtime.

Why Genuine Replacement Parts Are the Only Long-Term Fix

Grinder downtime solutions require more than quick fixes. The temptation to use cheap aftermarket parts creates long-term problems that far outweigh initial cost savings.

Cheap aftermarket parts present serious risks: dimensional misfits, shorter operational lifespans, and higher downtime frequency. These components often fail prematurely, creating secondary damage that compounds repair costs.

OEM-quality parts deliver precision manufacturing, extended durability, and guaranteed compatibility. GCH Tool Group maintains an extensive inventory of OEM-grade double disc grinder parts and accessories for immediate replacement needs. With over 10,000 parts in stock for all grinder types and brands, GCH provides the components necessary to restore peak performance.

GCH’s Remanufacturing & Exchange Program: Minimize Downtime, Maximize Precision

GCH Tool Group’s remanufacturing exchange program revolutionizes equipment maintenance by offering immediate replacement components. This innovative approach ships remanufactured components immediately upon request. Once replacements are installed, manufacturers ship damaged components to GCH for refurbishment and credit.

The rigorous remanufacturing process uses genuine parts and restores components to OEM standards—often better than original specifications. Available components include spindle assemblies, dresser units, wheelhead and slide assemblies, gearbox assemblies, feedbox and hydraulic valve assemblies, and other precision subassemblies used in double disc grinding systems.

This grinder part exchange model minimizes downtime while ensuring precision restoration. The final remanufactured product delivers a “better than new” performance with the reliability of genuine components.

Contact GCH Tool Group to Restore Your Double Disc Grinder’s Precision

The five critical wear zones—spindles and bearings, feed systems, structural backbone, power and motion components, and control systems—determine your grinder’s precision and productivity. Precision loss equals production loss, but both are preventable with genuine replacement parts and proactive maintenance.

GCH Tool Group stocks thousands of custom double disc grinder parts and components manufactured to exceed OEM specifications. All parts are guaranteed for maximum performance and available for same-day shipping worldwide.

Seeking to restore your double disc grinder’s precision with genuine replacement parts? Contact GCH Tool Group today for more information on GCH grinder parts and solutions. Our expert technical support and comprehensive inventory ensure your equipment delivers consistent, accurate results that keep your production schedule on track.