Cincinnati Grinder Ball Screw Accuracy: A Complete Guide

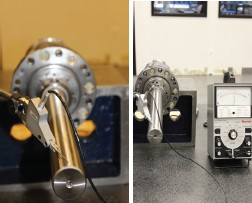

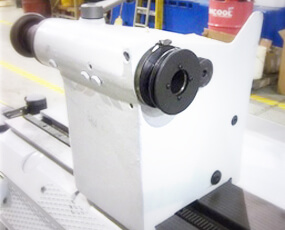

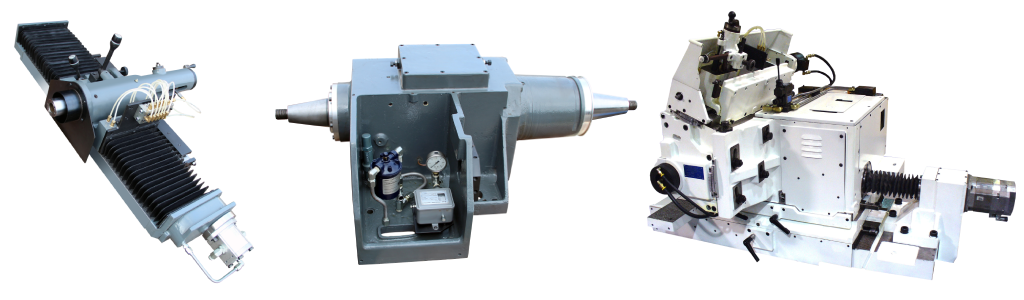

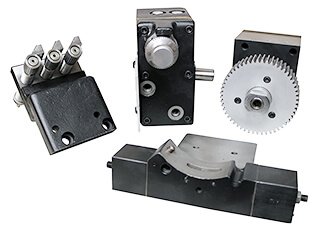

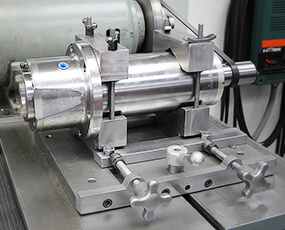

Ball screws are the backbone of precision grinding. They convert rotary motion into linear motion, enabling Cincinnati Milacron grinders to position workpieces with micron-level accuracy. By translating rotary motion into..