Precision Grinding: The Role of Work Rest Assemblies & Blades

Grinding and regulating wheels receive the most attention when it comes to high-precision manufacturing, but two often-overlooked components—work rest assemblies and centerless blades—play a crucial role in the machine’s performance. The interaction between these parts is vital; any misalignment or wear in either component can directly impact dimensional control, surface finish, and overall part quality.

Understanding how these parts work together is key to improving output, reducing scrap, and minimizing costly downtime. This guide will explore their functions and highlight why quality grinder replacement parts are essential for maintaining peak performance.

The Role of Work Rest Assemblies in Centerless Grinding

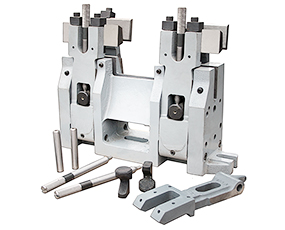

A work rest assembly is the mechanical structure that positions and supports the centerless blade. It sits between the grinding and regulating wheels, creating a stable platform for the workpiece. Think of it as the bedrock upon which precision is built.

Main Functions of Work Rest Assemblies

The assembly performs several critical functions to ensure a stable and accurate grind:

- Supports the workpiece: It provides a solid base for the centerless blade, which in turn holds the part securely.

- Maintains consistent positioning: It ensures the workpiece is held at the correct height and angle relative to the wheels.

- Prevents deflection or movement: By keeping the workpiece stable, it prevents unwanted movement that could cause dimensional inaccuracies.

- Helps achieve uniform material removal: Stable support allows the grinding wheel to remove material evenly across the part’s surface.

Common Issues That Affect Performance

Even the most robust work rest assemblies can develop issues that compromise grinding quality. Some common issues with work rest assemblies include:

- Worn-out contact surfaces: Wear on the assembly can cause the blade to sit unevenly, leading to inconsistent grinds.

- Incorrect alignment or angle: Improper setup can throw off the entire grinding geometry, resulting in tapered or out-of-round parts.

- Loose components: Vibration can loosen bolts and other parts over time, affecting the assembly’s rigidity.

The Role of Centerless Blades in Centerless Grinding

The centerless blade acts as a fixed support that holds the workpiece in place as it rotates between the grinding and regulating wheels. It ensures the part maintains the correct height and positioning, controlling the point of contact and the line of action for a consistent, precise grind.

Types of Centerless Blades & Their Applications

Blades come in various materials and designs, each suited for different applications:

- Carbide-tipped blades: Highly durable and wear-resistant, these are ideal for high-volume production or grinding hard materials. Their longevity makes them a cost-effective choice for demanding jobs.

- Steel blades: A more economical option, steel blades are often used for general-purpose applications or with softer materials where extreme wear resistance is not required.

- Custom or notched blades: These are specially designed for parts with unique geometries, such as those with multiple diameters or grooves, ensuring proper support during grinding.

The Impact of Blade Wear on Grinding Quality

A worn or damaged blade can cause a cascade of problems, including:

- Out-of-round parts: Uneven wear on the blade surface prevents the workpiece from rotating uniformly.

- Surface finish degradation: A rough or chipped blade can transfer imperfections onto the part’s surface.

- Excessive machine wear: A worn blade can cause vibrations that put additional strain on other centerless grinder components.

- Part rejections: Ultimately, blade wear leads to parts that fail to meet tolerance specs, increasing scrap rates.

Warning Signs That It’s Time for an Inspection

Proactive centerless grinder maintenance is crucial. Look for these signs of grinder wear that indicate your work rest assembly or blade needs attention:

- Scoring or groove wear on the blade surface.

- Visible misalignment of the work rest arm.

- A noticeable decline in the part’s surface finish.

- Difficulty holding tight tolerance specifications consistently.

The Importance of Quality Replacement Parts

When it’s time for a replacement, opting for high-quality grinder parts and accessories is a strategic decision. Precision-engineered components offer significant advantages:

- Extended Tool Life: Superior materials and manufacturing are key to extending the lifespan of the grinder.

- Consistent Precision: Parts made to exact OEM specifications ensure a perfect fit and reliable performance.

- Optimized Performance: Quality centerless grinder components work together seamlessly, reducing vibration and improving overall machine efficiency.

- Reduced Overall Costs: While the initial investment may be higher, durable parts reduce the frequency of replacements and minimize downtime, lowering total ownership costs.

Choosing the Right Replacement Parts: What to Look For

GCH Tool Group offers precision-engineered parts designed to work seamlessly with leading grinder brands, ensuring optimal performance and long-term reliability. From carbide-tipped and tool steel components to ceramic options, the right material selection makes a significant difference in wear resistance and efficiency for your centerless grinder.

Make sure to weigh the benefits of OEM versus aftermarket parts, considering critical factors such as tolerances, fit, and durability. Equally important are proper dimensions and secure mounting, which directly affect both machine performance and operator safety.

By partnering with GCH Tool Group, you can be confident that every replacement part meets the highest standards of quality and precision.

Protect Your Precision with GCH Tool Group

Investing in high-quality grinder replacement parts is not just about fixing a problem—it’s about implementing a preventative maintenance strategy that protects your machine and your output. GCH Tool Group provides a complete range of precision-engineered replacement parts for all major centerless grinder brands. Our OEM grinder parts are manufactured to meet or exceed OEM tolerances, ensuring you get the durability and performance needed to keep your operations running smoothly.

Don’t let worn parts compromise your quality. Contact us today to find the right precision grinding tools and components for your grinder.