The Lifecycle of Landis OD Grinder Parts: When to Repair, Replace, or Upgrade

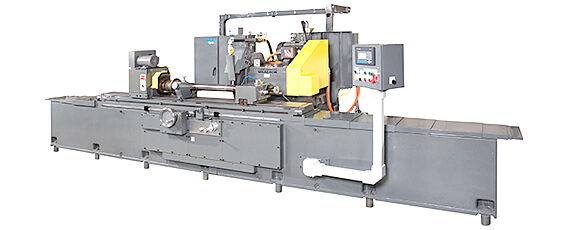

Landis OD grinders are renowned for their precision and durability, but this performance hinges on the integrity of their components. Every part is engineered to work in harmony, and when one fails, the entire system is compromised. Making the wrong call on whether to repair, replace, or upgrade a failing component can lead to costly downtime, increased scrap, and a significant drop in output quality.

To avoid these issues, manufacturing units need a strategic framework for managing their grinder components. Adopting a “lifecycle approach” helps you understand the health of your machine’s parts and make informed decisions that protect your investment. This guide will walk you through the lifecycle of Landis OD grinder parts and explain when to repair, replace, or upgrade to maintain peak performance.

Understanding the Lifecycle of OD Grinder Parts

In the context of industrial machinery, a part’s “lifecycle” refers to its journey from initial installation to eventual failure. For key components like spindles, bearings, and guideways, this journey involves predictable wear-and-tear patterns. Initially, performance is optimal. Over time, subtle dips in efficiency occur, which can escalate to critical failure risks if ignored. Recognizing the signs of grinder part wear is crucial for proactive maintenance or for restoring Landis precision.

When to Repair: Extending the Life of Worn Parts

Deciding when to repair Landis grinder parts is a cost-benefit analysis. A repair can be a quick and economical solution if the damage is minimal and the part is not critical to the machine’s core precision.

Situations where repair makes sense include:

- Minor wear where the part’s geometry is still intact

- Early-stage damage that has not compromised the component’s function

- Slight performance dips where the part is still operating within acceptable tolerances

- Non-critical parts where a temporary fix is sufficient

While repairing offers the benefit of lower short-term costs and faster turnaround, it has limitations. A repaired part may not deliver the same level of precision as a new component, potentially impacting the quality of your finished products.

When to Replace: Restoring Landis Precision and Reliability

Replacement becomes necessary when a part is too worn or damaged to function reliably. Frequent breakdowns, visible surface finish defects, and an inability to hold tolerances are clear indicators that a replacement is due. For example, a regulating wheel spindle that is severely worn or damaged is beyond repair and must be replaced to prevent catastrophic failure.

Replacing worn components with high-precision grinder components offers significant benefits:

- Restores OEM Precision: New parts guarantee the accuracy your Landis grinder was built for.

- Improves Consistency: It eliminates the variability caused by worn or failing parts.

- Reduces Downtime: Proactive replacement prevents unexpected breakdowns and production halts.

So, investing in high-quality OD grinder replacement parts is essential for maintaining operational stability and product quality.

When to Upgrade: Taking Landis OD Grinders Further

Sometimes, simply replacing a part isn’t enough. OD grinder upgrades can modernize your machine, enhancing its capabilities to meet today’s demanding manufacturing standards.

Upgrades like modernized controls, improved automation options, and enhanced gaging systems can significantly boost throughput and efficiency. For example, upgrading to advanced CNC controls can drastically reduce cycle times, extending the productive life of your Landis OD grinders.

The Risks of Delaying Part Decisions

Postponing decisions about worn parts can have severe consequences. What starts as a minor issue can lead to costly catastrophic failures, increased scrap rates, missed delivery deadlines, and even operator safety risks. The financial impact of unplanned downtime and scrapped production often far exceeds the cost of a replacement part. Using low-quality alternatives and not recognizing the risks of counterfeit grinder parts only compound these dangers.

GCH Tool’s Remanufacturing Exchange Program

To minimize downtime while maximizing precision, GCH Tool offers a grinder remanufacturing exchange program for Landis OD grinders. This program allows you to swap worn parts for fully remanufactured, genuine-quality replacements.

The benefits of our exchange program include:

- OEM-level accuracy and reliability

- Shorter lead times compared to new parts

- Reduced costs without sacrificing quality

Unlike generic refurbishers, GCH Tool uses only 100% new components in our remanufacturing process, ensuring every part meets or exceeds original specifications.

Keep Your Landis OD Grinders Running at Peak Performance

Making the right decision to repair, replace, or upgrade is vital for the longevity and performance of your Landis OD grinders. Cutting corners with subpar repairs or counterfeit parts jeopardizes precision, safety, and your bottom line.

GCH Tool is the leading supplier of OEM-compatible grinder accessories and Landis OD grinder parts. Our experts can provide the guidance you need to make the right choice, offering reliable and cost-effective solutions to keep your operations running smoothly.

Contact GCH Tool today to discuss your grinder part needs and ensure your machines continue to operate at their best.