Place one call and access our extensive inventory of 10,000 new parts and components for all grinder types and brands

Get the Grinder Parts and Components You Need

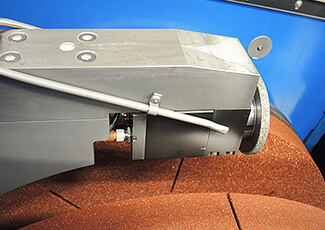

Double Disc Grinding Wheel Dressers

Efficiency and precision are vital in the demanding world of metalworking. Double-disc grinders play a pivotal role in achieving these objectives, significantly enhancing productivity and part quality. Central to maximizing the performance of these machines is the optimal use of grinding wheel dressers. These tools ensure the grinding wheels work as intended, keeping operations smooth and efficient.

The Role of Grinding Wheel Dressers

Grinding wheel dressers are indispensable tools in maintaining the effectiveness of double-disc grinders. By preserving the flatness and correct geometry of the grinding wheels, dressers optimize the metal removal process and improve the surface finish of the parts being machined. Furthermore, using the right double-disc grinding wheel dresser can extend wheel life, reduce machine downtime, enhance part quality, lower operational costs and even prolong the grinder’s lifespan.

Why Use a Grinding Wheel Dresser for Double-Disc Grinders?

The advantages of incorporating a quality grinding wheel dresser into your double-disc grinder setup are numerous:

- Maintaining Flatness and Geometry: Ensures consistent grinding accuracy, which is critical for the precision of the final product.

- Optimizing Stock Removal: Achieves efficient material removal rates by carefully balancing the rate of stock removal with the desired outcome.

- Improved Surface Finish: Delivers a superior finish on the final product, enhancing its appearance and functional properties.

- Extended Grinding Wheel Life: Reduces the need for frequent replacements while contributing to more consistent production quality.

- Reduced Downtime: Keeps machines running more smoothly and for longer periods by minimizing interruptions.

- Improved Part Quality: Guarantees parts meet stringent quality standards, ensuring they perform as expected in their final application.

- Increased Production Efficiency: Enhances overall operational throughput by streamlining processes, improving speed and reducing waste.

- Reduced Operating Costs: Lowers the expenses associated with wheel replacement and machine downtime.

- Enhanced Machine Longevity: Decreases wear and tear on valuable machinery.

Double-Disc Grinding Wheel Dressers by GCH Tool Group

GCH Tool Group offers premium grinding wheel dressers specifically designed for double-disc grinders:

- Diamond Rotary Dressers: These dressers use high-quality diamonds to provide unparalleled precision in dressing grinding wheels, ensuring optimal geometry and surface finish.

- Adaptor Kits: Customizable adaptor kits facilitate the integration of our dressers with various grinder models, including 30” and 42” Gardner SDG5 and Gardner SDG6 double-disc grinders, ensuring compatibility and maximizing utility.

Why Choose GCH Tool Group for Double Disc Grinding Wheel Dressers?

Selecting GCH Tool Group for your grinding wheel dressers brings several benefits:

- Remanufacturing Exchange Program: Minimize downtime without unnecessary inventory expenses through our innovative exchange program.

- High-Quality Dressers: Our diamond wheel dressers are made to precise standards, enhancing performance and longevity.

- Custom Solutions: Our experienced engineers can design and manufacture a custom grinding wheel dresser to suit your specific double-disc grinder and application.

- Unmatched Expertise: Leverage the deep industry experience of our team to find solutions that boost your productivity and efficiency.

With a commitment to service and value, GCH Tool Group offers competitive pricing, an industry-leading new warranty on all grinder parts and components and same-day shipping whenever possible.

Next Steps – Finding the Right Grinding Wheel Dresser

To ensure you select the ideal grinding wheel dresser for your double-disc grinder, consider the following factors:

- Double-Disc Grinder Model: Knowing your specific grinder model helps us identify compatible dressers or adaptor kits.

- Grinding Wheel Material: Different grinding wheel materials (e.g., aluminum oxide, cubic boron nitride) may require specific dresser types.

- Desired Workpiece Finish: The level of precision required for your finished parts may influence the dresser type needed.

Contact GCH Tool Group Today

Understanding and implementing the correct type of grinding wheel dresser for your double-disc grinders is crucial for maintaining efficiency, precision and cost-effectiveness in metalworking. GCH Tool Group stands as your premier partner in this endeavor, offering a comprehensive range of high-quality dressers, custom solutions and industry-leading expertise.

We are recognized as the world’s largest supplier to the grinder industry, providing unparalleled technical support and superior double-disc grinder parts and components.

Ready to enhance your double-disc grinding operations? Contact us today and discover how our grinding wheel dressers can transform your productivity and part quality.

Speak with one of our experienced sales engineers