Top Centerless Grinding Automation Upgrades That Deliver the Fastest ROI

Labor shortages, rising production demands, and increasingly tight precision requirements are creating a perfect storm for manufacturing shops. To stay competitive, relying solely on manual processes is no longer sustainable. However, buying brand-new machinery isn’t always the answer.

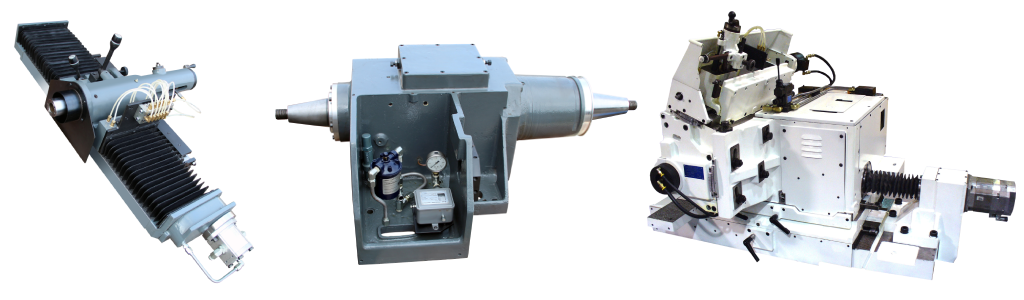

Many shops are discovering that their legacy centerless grinders can deliver new-level performance through strategic automation. By integrating modern technology into existing machines, manufacturers can achieve higher throughput and better quality without the capital expense of new equipment. As a global leader in grinder parts and upgrades, GCH Tool Group specializes in these high-impact transformations, enhancing existing machines with automation and precision upgrade components rather than replacing them, turning reliable workhorses into modernized automated grinding workstations.

How Centerless Grinding Automation Pays for Itself Quickly

Automation isn’t just about “robots replacing humans”; it’s about optimizing your resources to maximize profitability. When you upgrade a centerless grinder with automation, the return on investment (ROI) is often realized much faster than expected.

Cuts Manual Labor & Handling Dependence

One of the most immediate benefits of centerless grinding automation upgrades is the reduction in manual intervention. By automating the feeding and positioning processes, you reduce the need for an operator to stand by the machine for every cycle. This direct labor savings lowers operating costs and allows your skilled staff to focus on higher-value tasks, such as quality control or managing multiple machines, rather than repetitive loading.

Increases Throughput, Cycle Time Consistency, & Machine Utilization

Humans vary in speed and consistency; machines do not. Automation ensures a consistent production flow, eliminating the natural variances in manual loading. This reliability improves scheduling and planning, allowing you to get more parts out the door. You increase profitability by boosting machine utilization rates without investing in additional floor space or new machines.

Improves Accuracy & Reduces Scrap

Human error—whether it’s a slight misalignment during loading or fatigue-induced mistakes—leads to scrap. Automation delivers precise, repeatable handling every single time. This reduction in rework, regrinding, inspections, and rejected parts directly connects to your bottom line, further accelerating your ROI.

Supports Extended or Lights-out Production

Perhaps the most powerful ROI driver is the ability to run “lights-out.” With the right automated systems, your centerless grinder can continue producing through breaks, shift changes, or even overnight with minimal supervision. Achieving multi-shift output on a single shift’s labor cost dramatically boosts your competitiveness.

Centerless Grinder Upgrades That Pay for Themselves

Not all upgrades are created equal. The following technologies are proven to deliver the most significant impact on productivity and cost-efficiency.

Automatic Loading & Unloading Systems

These systems mechanically handle the raw material entering the machine and the finished parts exiting it.

- Key Benefits: You achieve higher production per shift and significantly reduce operator fatigue. Furthermore, consistent mechanical handling lowers the risk of part damage and handling errors that often occur during manual transfers.

Robotic Automation for High-Volume & Multi-Shift Production

For shops dealing with high volumes, robotic or automated part handling solutions (including gantry loaders, conveyors, or collaborative robots) are a game-changer. These systems provide consistent, programmed part transfer and are designed for continuous operation.

- Key Benefits: The result is reduced labor costs and throughput that’s up to two to three times. Robots also offer improved repeatability, ensuring every part is handled with the exact same pressure and orientation.

Automatic Gauging & Closed-Loop Size Control

This technology measures parts in real time using in-process probes or sensors and automatically adjusts the machine to maintain tolerances through closed-loop size control with feedback to the control system.

- Key Benefits: This significantly reduces scrap generation and rework. You achieve tighter tolerances and consistent finishes while reducing the frequency of dressing and setup adjustments required by operators.

Automated Part Feeding & Orientation Systems

Automated loading systems like bowl feeders organize and orient bulk parts for continuous entry into the grinder.

- Key Benefits: Continuous grinding flow supports high-capacity and unattended production, effectively reducing cycle time loss caused by manual sorting and feeding.

Coolant Management & Filtration Automation

Clean coolant is critical for precision. Automatic coolant filtration systems ensure that the fluid remains free of swarf and debris through magnetic separators, skimmers, or filtration units without constant manual cleaning.

- Key Benefits: This leads to longer grinding wheel life and reduced surface burns or heat damage. It also lowers maintenance requirements and results in fewer machine breakdowns due to contaminated fluid.

Servo Drive Transmission Conversion

Replacing older hydraulic or mechanical transmissions with modern servo drives allows for precise digital control over the grinding process.

- Key Benefits: Shops experience reduced maintenance, lower vibration, improved roundness, superior surface finishes due to smoother operation, and greater energy efficiency compared to older hydraulic systems.

Dressing System Automation

Automated dressing ensures the grinding wheel is conditioned exactly when needed, removing the variability of manual dressing.

- Key Benefits: This delivers consistent wheel conditioning, improved part accuracy, and tolerance control. It also extends wheel life and eliminates the inconsistencies caused by manual dressing techniques through CNC-controlled profiling and truing operations.

Machine Monitoring & Data Automation

Modern upgrades can include sensors and software that track machine health and production metrics, such as spindle load, vibration, temperature, and cycle counts.

- Key Benefits: Data automation allows for predictive maintenance, reducing unexpected downtime. It empowers better decision-making and overall machine optimization based on real-time performance data displayed through HMIs or plant monitoring systems.

Why Centerless Grinding Automation Upgrades Beat Buying a New Grinder

When weighing the options, upgrading the centerless grinder often makes more financial sense than replacing the whole machine. CNC retrofits for centerless grinders and automation packages typically cost 50–80% less than purchasing new equipment. Beyond the price tag, upgrades offer faster installation times, meaning you achieve ROI quicker.

Upgrading extends the life of existing machines that are already producing reliably, ensuring you don’t lose the value of your current assets. Crucially, GCH Tool Group can implement these solutions even on older or unsupported OEM grinder models, provided the mechanical platform remains structurally sound, giving new life to equipment you might have thought was obsolete.

Automation Is No Longer Optional

In today’s market, automation is no longer optional for shops competing on cost, speed, and precision. The right upgrades unlock higher output, lower costs, and longer machine life, transforming your existing floor into a high-performance production environment.

GCH Tool Group is the industry authority on grinding upgrades and OEM-grade centerless grinder replacement parts. With the world’s largest inventory of centerless grinder parts and components, we have the expertise and the hardware to modernize your operations.

Start your centerless grinding automation journey with GCH Tool Group today.