Benefits of Automating Grinding Operations

If you are considering the benefits of automation for your shop operations, there are many compelling reasons to make the switch. Automated machines can address pain points such as high labor costs, inconsistent quality and operator safety concerns.

Additionally, they can help you stay ahead of the competition by lowering your cost per part and increasing your production capacity. Ultimately, automating your grinding operation can provide significant advantages for your business.

Here are just a few of the benefits you can expect

Reduce Labor Costs

One of the key benefits of automating your manufacturing process is the significant reduction in labour costs. By eliminating the need for operator intervention, you can save on employment costs. This is especially beneficial for small- and medium-sized manufacturers who may otherwise struggle to find adequate staff.

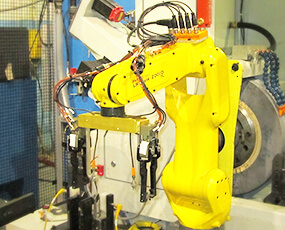

In addition, robots can handle repetitive and often unsafe tasks like loading and unloading without the possibility of human error. This not only makes your process more efficient but also helps to create a safer working environment. Ultimately, automating your process can save you time and money while helping to improve the quality of your product.

Utilize Your Human Capital More Efficiently

The increasing skills gap is expected to result in two million unfilled manufacturing jobs by 2025, according to Deloitte. Automation reduces the danger by expanding the capabilities of the labour force that already exists.

For example, over 90% of the required labour is completed by an OD grinder with a gantry load/unload robot on each shift. This means operators can manage several other machines in the production cell, generating value. Another set of less perceptible benefits include:

- As opposed having many people on hand to load a machine, planning for each batch will now be based on distinct requirements. Extra operations, for example, can be carried out during the day, and more automated procedures on second or third shifts.

- Robotics jobs are more appealing to tech-savvy youngsters. They frequently anticipate that the evolving 4.0 business will allow them to advance their skills and careers.

- Companies can not only improve efficiency and quality but also attract top talent by moving some employees into more effective jobs.

Enhance Productivity

Repeatable precision has a variety of benefits for your manufacturing unit. It lowers the cost per part, increases quality and uptime, and reduces errors. All of this leads to a more efficient and effective business operation.

Save Energy and Have a Smaller Footprint

According to the Association for Advancing Automation, automation systems consume less energy than their predecessors and produce “little wasted heat and utilize the minimum amount of power.”

The reduction of idling time and reduced heating and lighting expenses during unattended production may result in significant energy savings.

Automation also aids in the accommodation of current industry thinking about shop floor surface area usage thanks to loader systems with small footprints, overhead gantry style loaders and fenceless robots.

Also Read: How Automation in Centerless Grinding Is Transforming the Industry

Automate Your Grinding Process with GCH Tool Group

GCH Tool Group is a leading provider of grinding automation solutions. We offer a range of robotic and varied automation systems to suit your needs. We also provide training and support to ensure that your team is able to effectively use grinding automation in your business.

We offer a variety of tools to help you automate machine operations, including

- Robotic systems

- Part hoppers

- Bar feeders

- Bowl fixtures

- Overhead gantries

- Conveyor systems

- Single and double loaders

Contact us today if you’re searching for a grinding automation solution that can help your production line reach new heights.