Why You Need Automatic Grinding Wheel Balancers

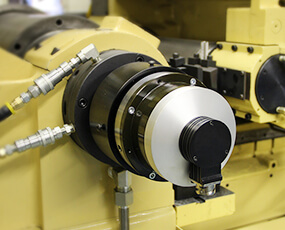

Automatic grinding wheel balancers make a substantial difference in the efficiency and precision of your grinding machines. With modern machines boasting much higher rpms, an unbalanced grinding wheel can hamper your production lines or deliver inferior results.

Let’s take a deeper look at automatic grinding wheel balancers and how they can help your business.

What Causes Unbalanced Grinding Wheels?

Automatic grinding wheel balancers are designed to counteract the threat of unbalanced grinding wheels.

As mentioned above, unbalanced grinding wheels can hurt productivity and quality. But how do they become unbalanced?

There are a variety of reasons a grinding wheel may become unbalanced, including:

- The wheel bore can no longer tolerate the strain

- Inner quality uniformity

- Mixed material is uneven

- Fitting conditions are different, with contraction and reaction results in uneven density

- The two ends are no longer parallel (parallelism)

Those are just some of the main causes. This means that as you use your grinder,it’s very possible that eventually you may encounter an unbalanced grinding wheel.

Problems Due to Grinding Wheel Unbalances

If your grinding wheels are unbalanced,it could lead to a number of negative effects on your grinding machines and their work output.

An unbalance could lead to:

- Reduction in surface quality

- Reduction in dimensional accuracy

- Significantly higher grinding wheel wear

- Spindle head wear

How Can Automatic Grinding Wheel Balancers Help Balance Your Grinding Wheels?

When faced with unbalanced grinding wheels, many have turned to an automatic grinding wheel balance system.

This system controls the intensity of the vibrations received by the grinding wheel and automatically calibrates to compensate for any imbalance detected. In addition to helping your machines last longer (and reduce downtime) so you can get optimal value out of them, it will help:

- Improve the lifespan of the grinding wheel spindle

- Increase the lifespan of dressing tools

- Reduce dress passes

- Enhance grinding wheel life

- Help to reduce the possibility of chatter or out-of-roundness issues

- Decrease size variation

In other words, if you find yourself running into problems due to an unbalanced grinding wheel, an automatic grinding wheel balancing system can be an excellent and cost-effective solution.

Get Automatic Grinding Wheel Balancers and Other Accessories at GCH Tool Group Inc.

GCH Tool Group is a leading provider of grinding automation solutions, including automatic grinding wheel balancers.

We offer a range of robotic and varied automation systems to suit your needs. We also provide training and support to ensure that your team is able to effectively use grinding automation in your business.

We offer a variety of tools to help you automate machine operations, including:

- Robotic systems

- Part hoppers

- Bar feeders

- Bowl fixtures

- Overhead gantries

- Conveyor systems

- Single and double loaders

Contact us today if you’re searching for a grinding automation solution that can help your production line reach new heights.