Place one call and access our extensive inventory of 10,000 new parts and components for all grinder types and brands

Get the Grinder Parts and Components You Need

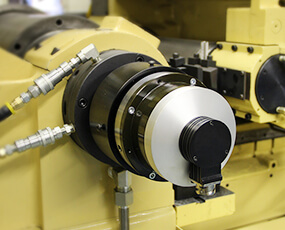

Grinding Wheel Automatic Balancers

Is an automatic grinding wheel balancer a worthwhile investment? If you want to extend the life of your grinder, improve part quality or reduce abrasive costs and cycle time then the answer is a resounding yes.

An automatic wheel balancing system can improve your grinding by:

- Improving the lifespan of the grinding wheel spindle

- Increasing the lifespan of dressing tools

- Decreasing machine downtime

- Reducing dress passes

- Enhancing grinding wheel life

- Helping to reduced the possibility of chatter or out-of-roundness issues

- Decreasing size variation

We Offer Top-Of-The-Line Retrofit Balance Systems

GCH offers top-of-the-line retrofit balance systems designed to operate in the harshest conditions of a production grind. Engineered to accommodate most centerless grinding machines, these systems measure the level of vibration caused by the unbalanced wheel, and automatically position counterweights to cancel the unbalance in the wheel. The operation can be fully automatic to preset limits or can be controlled by the operator who would press a single button to start the cycle.

Special AE (acoustic emission) sensors, available on some systems, show via the machine’s control system when the grinding wheel makes contact with the dressing tool or work part. AE sensors eliminate grind cycle gap time in the grinding cycle.

GCH Tool Group offers many accessories to increase productivity and part quality while decreasing the maintenance cost of your centerless grinders. Wheel balancers are typically installed on centerless grinders. We can also evaluate whether a wheel balancer would be appropriate for other types of grinders including surface grinders.

Speak with one of our experienced sales engineers