How Mist Collectors and Enclosures from GCH Tool Group Elevate Precision Machining

In the world of industrial manufacturing, precision machining is paramount. With the high standards and expectations placed on the production of complex parts, every detail matters. Unfortunately, airborne contaminants produced during this process can have a negative impact on the quality and accuracy of machined parts, leading to costly errors and delays.

That’s where GCH Tool Group’s grinding mist collectors and enclosures come into play. These solutions are a game-changer for manufacturers, helping to keep their environments safe and clean while ensuring the continued delivery of quality products. By efficiently capturing and containing harmful contaminants including dust, metals and chemical compounds, mist collectors and enclosures not only help maintain precision grinding but also support the health and safety of workers in the plant.

The Challenges of Contaminants in Precision Machining

The Hidden Enemy: Airborne Contaminants

While the importance of precise tools and skilled operators is undeniable, the often-overlooked element in precision grinding is airborne contamination. Tiny particles from cutting fluids, grinding dust and metal shavings can easily infiltrate work areas, causing a multitude of problems:

- Reduced surface finish quality: Contaminants can scratch and mar delicate surfaces, compromising the final product’s aesthetics and functionality.

- Diminished accuracy and dimensional stability: Abrasive particles can affect tool wear and performance, leading to dimensional inaccuracies and inconsistent results.

- Premature tool wear and tear: Dust and debris can clog tool paths and increase friction, accelerating tool wear and requiring more frequent replacements.

- Health and safety concerns: Airborne particles pose a significant health risk to operators, potentially causing respiratory problems and irritation.

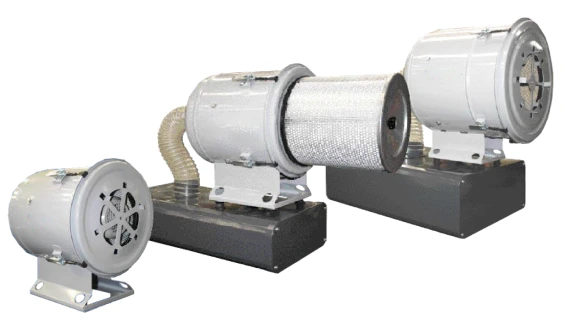

Mist Collectors: Filtering Out Impurities

Mist collectors, also known as oil mist collectors, are a type of industrial dust collector that specifically functions to collect and filter oil mist, coolant mist and other fine particles in the grinding process. Grinding mist collectors are mounted wherever mist control is needed, ideally above or on the side of the grinder. This ensures the effective containment of mist.

GCH Tool Group’s State-of-the-Art Mist Collectors

GCH Tool Group’s mist collectors boast advanced features and benefits such as:

- High-efficiency multi-stage filtration systems

- Automatic operation and self-cleaning mechanisms

- Customizable configurations for various applications

Reap the Benefits of Clean Air

These machines are essential for removing hazardous particles from the air and maintaining a clean and safe work environment. Mist collectors can improve surface finish, dimensional accuracy, tool life and operator health and safety, offering:

- Reduced marring for superior finish quality

- Minimized tool wear for precise machining

- Cleaner environment for extended tool life and operator comfort

- Reduced exposure to health risks

Enclosures: Building a Fortress for Precision

A grinder enclosure is essentially a safety barrier that surrounds the grinding area. Not only does this help prevent accidents and injuries, but it also helps contain debris and dust particles that can be harmful to workers.

Like mist collectors, machining enclosures can also improve the quality of the grinding process by keeping the area free of contaminants that could potentially compromise the finished product.

GCH Tool Group’s Precision-Engineered Enclosures

In response to the growing demand for stringent safety standards in grinding machine operations, GCH has developed a comprehensive range of full and partial mist enclosures.

Designed to cater to all centerless, OD, ID and double-disc grinders, our enclosures include features such as:

- Transparent polycarbonate or steel construction for visibility and protection

- Interlock systems for safety and operator convenience

- Integrated lighting and ventilation for optimal environment control

Fortifying Your Machining Process

Enclosures can enhance contaminant control, temperature and humidity levels, operator comfort and safety, providing:

- A virtually dust-free environment for exceptional precision and surface finish

- A controlled environment for consistent results and machine protection

- Improved air quality and noise reduction for operator well-being

- Added protection against accidental damage

The Synergistic Power of Both Solutions

Airborne contaminants in machining can pose a significant risk to operator safety and equipment efficiency. The use of both mist collectors and enclosures offers synergistic benefits that address these concerns.

When operated in tandem, these tools provide:

- Extended filter life and reduced maintenance costs

- Enhanced airflow and pressure control for superior filtration

- Maximum operator protection from dust and airborne particles

Invest in Your Success

Partnering with GCH Tool Group brings superior solutions to your machining needs. Our clients enjoy:

- Superior quality and accuracy in machining results

- Extended tool life and minimized downtime

- A safer and more productive work environment

Our commitment to quality and accuracy results in top-performing machine tools that produce exceptional results—not just once, but time and time again. Safety-conscious workplaces with productive employees are a hallmark of our designs and our team is committed to providing the safest and most productive environment possible.

Choose GCH Tool Group’s Advanced Mist Collectors and Enclosures

Clean air is essential to our health and well-being, but it’s also vital in the world of precision machining. That’s why GCH Tool Group’s innovative mist collectors and enclosures are so transformative. Their cutting-edge technology not only ensures a healthier work environment, but also leads to more accurate and efficient machining.

The importance of clean air cannot be overstated, and our solutions offer a powerful way to achieve it. If you’re looking to optimize your machining processes, contact us today and explore the high-quality grinder accessories, tools, parts and components and many other offerings available, including mist filters for CNC grinders.