Cylindrical Grinder 101: Understanding the Role of Headstock and Tailstock

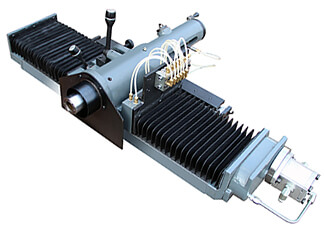

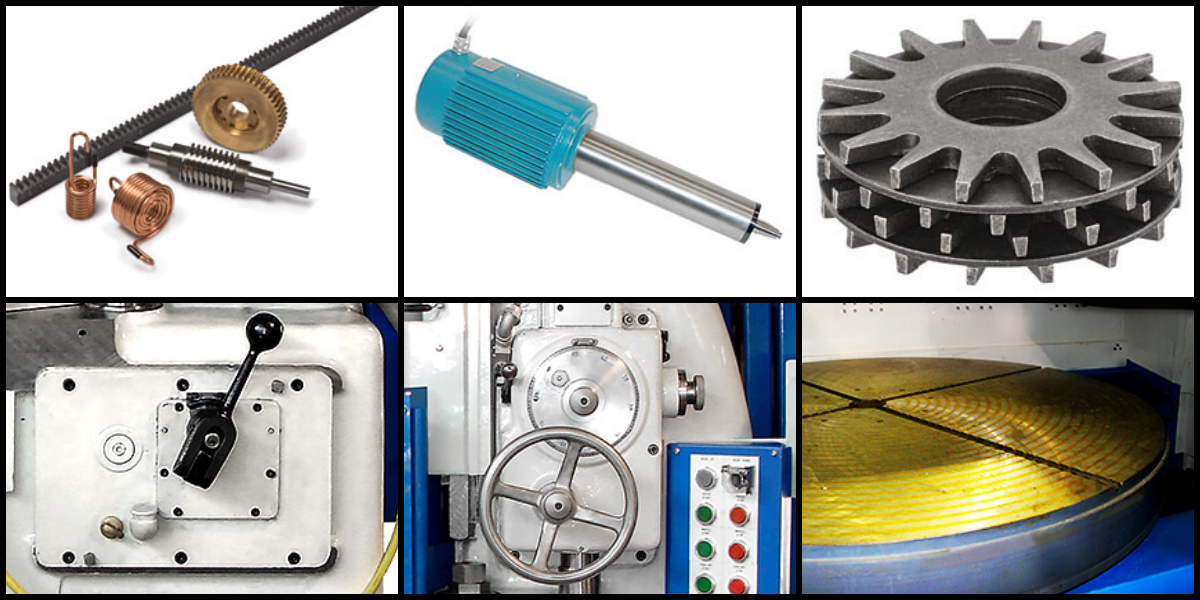

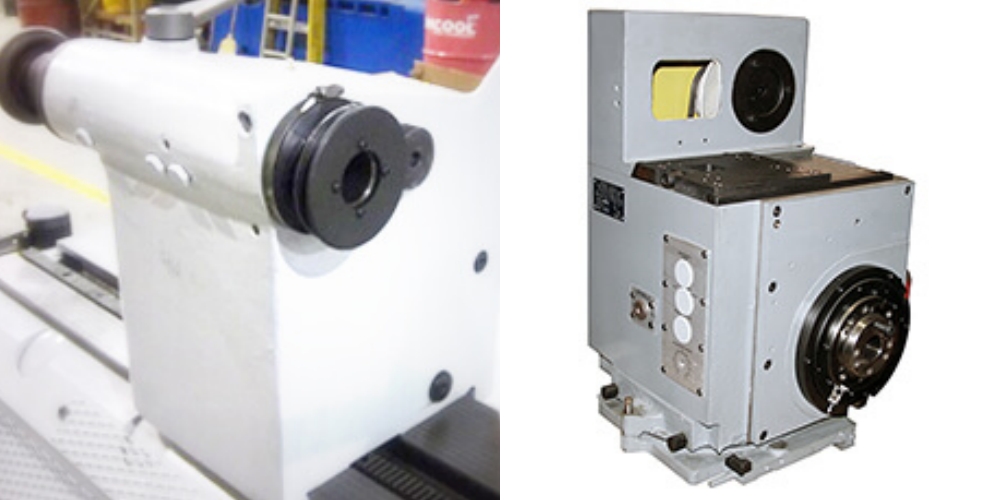

A cylindrical grinder is designed to reshape the exterior of objects into a precise cylindrical silhouette. The headstock and tailstock of these specialized grinding machines, commonly referred to as OD grinders or OD grinding machines, play pivotal roles that both beginners and seasoned machinists must master. These fundamental components are crucial for achieving unparalleled precision … Cylindrical Grinder 101: Understanding the Role of Headstock and Tailstock