What Causes Spindle Failure and How Can You Repair Them?

Spindle failure is a common issue that can occur in any type of manufacturing or production environment. There are a variety of causes of spindle failure, and each one requires a different approach to repair. The most common cause of spindle failure is impact with workpieces or due to bearing failures.

In this article, we will discuss the most common causes of spindle failure and the important steps involved in repairing them. We will also take a look at GCH Tool Group’s spindle repair services and what makes them the best choice for your business.

What Are the Common Causes of Spindle Failure?

Impact with Work Material

One of the most common causes of spindle failure is impact with work material. This can occur if the work material is too hard or if it has a sudden change in direction. When the spindle hits the work material, it can cause damage to the bearings, shaft, and other components.

Handling and Storage Mistakes

Mishandling of the spindle can also cause it to fail. This can include dropping the spindle or subjecting it to excessive vibration. Storage in an improper environment can also lead to spindle failure. Storage temperature fluctuations and high humidity can cause the spindle to rust or corrode.

Improper Installation or Removal

Another common cause of spindle failure is improper installation or removal. This can occur if the spindle is not installed correctly or if it is removed without following the proper procedure. Improper installation or removal can damage the bearings, shaft, and other components.

Excessive Vibration

Another common cause of spindle failure is excessive vibration. This can be caused by a number of factors, including imbalanced components, loose bolts, or worn bearings. Excessive vibration can damage the spindle and cause it to fail.

Poor Lubrication Application

One of the most common causes of spindle failure is poor lubrication. When bearings are not properly lubricated, they can overheat and fail. This can cause extensive damage to the spindle and lead to costly repairs. Using too much or too little lubricant can also cause spindle failure. If there is not enough lubricant, bearings can seize up. If there is too much lubricant, it can cause bearings to overheat and fail.

Dirty, Contaminated, or the Wrong Type of Lubricant

Dirty or contaminated lubricant can also cause spindle failure. This can result in bearings seizing up and failing. Using the wrong type of lubricant also raises the risk of failure.

Using the Wrong Type of Tooling

Using the wrong type of tooling can also cause spindle failure. This can result in the tooling becoming damaged or worn out prematurely.

Not Following the Manufacturer’s Recommendations

Not following the manufacturer’s recommendations can also cause spindle failure. This can result in damage to the spindle or bearings.

Overloading the Spindle

Overloading the spindle can also cause it to fail. This can happen if the spindle is not properly rated for the weight of the workpiece.

Dirty or Contaminated Coolant

Another common cause of spindle failure is dirty or contaminated coolant. Coolant that is not properly cleaned can cause bearings to seize up and fail.

Air or Chip Contamination through Improper Air Hose Use

Air or chip contamination can also cause spindle failure. This is usually caused by improper use of an air hose for cleaning such as excessive air pressure.

What Is the Spindle Repair Process?

It’s possible to repair the spindle if it hasn’t been subject to too much damage. These are some important steps in the spindle repair process:

Inspect the Spindle

The first step in repairing a spindle is for professional technicians to inspect it for damage. This includes checking for cracks, chips, or other damage so as to gauge the condition of the parts for wear and tear. The main focus is to identify the cause of spindle failure.

Disassemble the Spindle

The next step is to disassemble the spindle. This includes removing the bearings, shaft, and other components. The disassembling process is carried out in a clean environment to ensure there is no contamination. Each part is thoroughly examined and photographed. A deeper analysis can then be done to have a better understanding of the failure.

Clean the Spindle

Once the spindle is disassembled and examined, it is then cleaned. This includes removing all dirt, debris, and contaminants. It may also be machined or ground depending on the spec requirements.

Inspect the Bearings and Shaft

The next step is to inspect the bearings and shaft. This includes checking for wear, damage, or other problems. It’s also important to check the shaft for straightness.

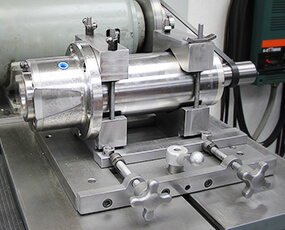

Repair the Spindle

Once all the parts are inspected, they are then repaired or replaced as necessary. The repair or re-building is carried out in an area fitted with essential equipment and facilities operated by expert technicians. The repair process includes machining, grinding, or other operations as required. All the parts are then cleaned and inspected again.

Check the Balance

After the spindle is reassembled, it is then checked for balance. Unbalanced parts pose a risk leading to future spindle failures. The balance is restored by adding or removing material and weight. This is done to ensure that the spindle runs smoothly and does not vibrate excessively.

Reassemble the Spindle

Once the spindle is inspected and cleaned, it is then reassembled. This includes installing the bearings, shaft, and other components.

Test the Spindle

The final step is to test the spindle. The testing is done is a separate testing area. This includes running it under various loads to check for proper operation. It will be tested for important metrics like speed, temperature, and vibration. The spindle then undergoes a final quality assurance check to ensure it meets the manufacturer’s specifications.

Spindle Repair and Rebuild Services at GCH Tool Group

GCH Tool Group is the leading provider of spindle repair services based in the United States. We have over 30 years of experience repairing all types of spindles for our global clientele.

Our team of experts is ready to help you get your production line back up and running. We offer a free consultation to help you determine the best course of action for your specific needs. Contact us today to learn more about our spindle repair and rebuild services.