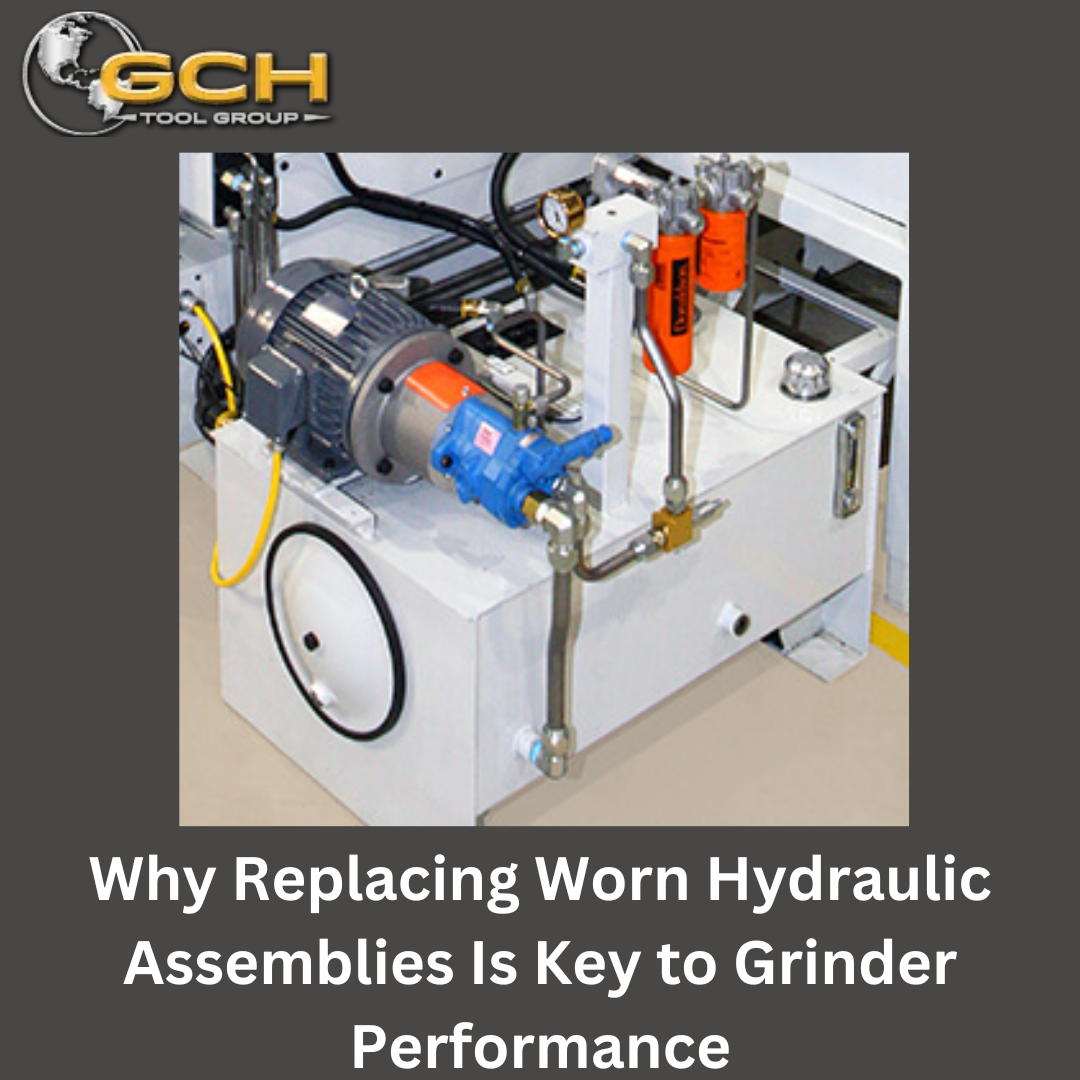

Why Replacing Worn Hydraulic Assemblies Is Key to Grinder Performance

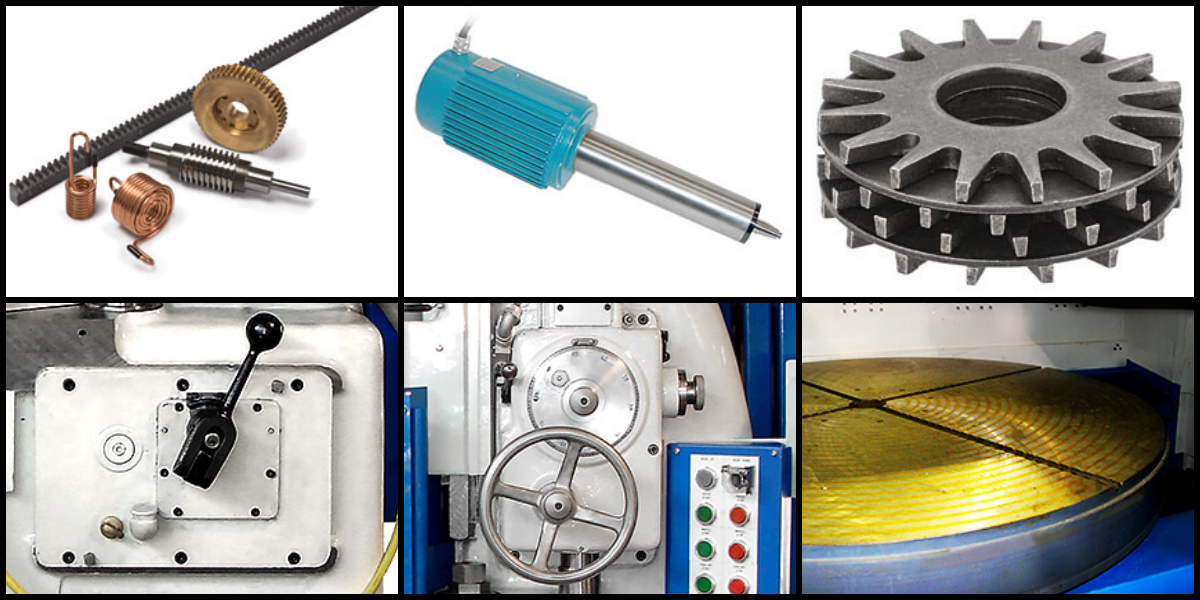

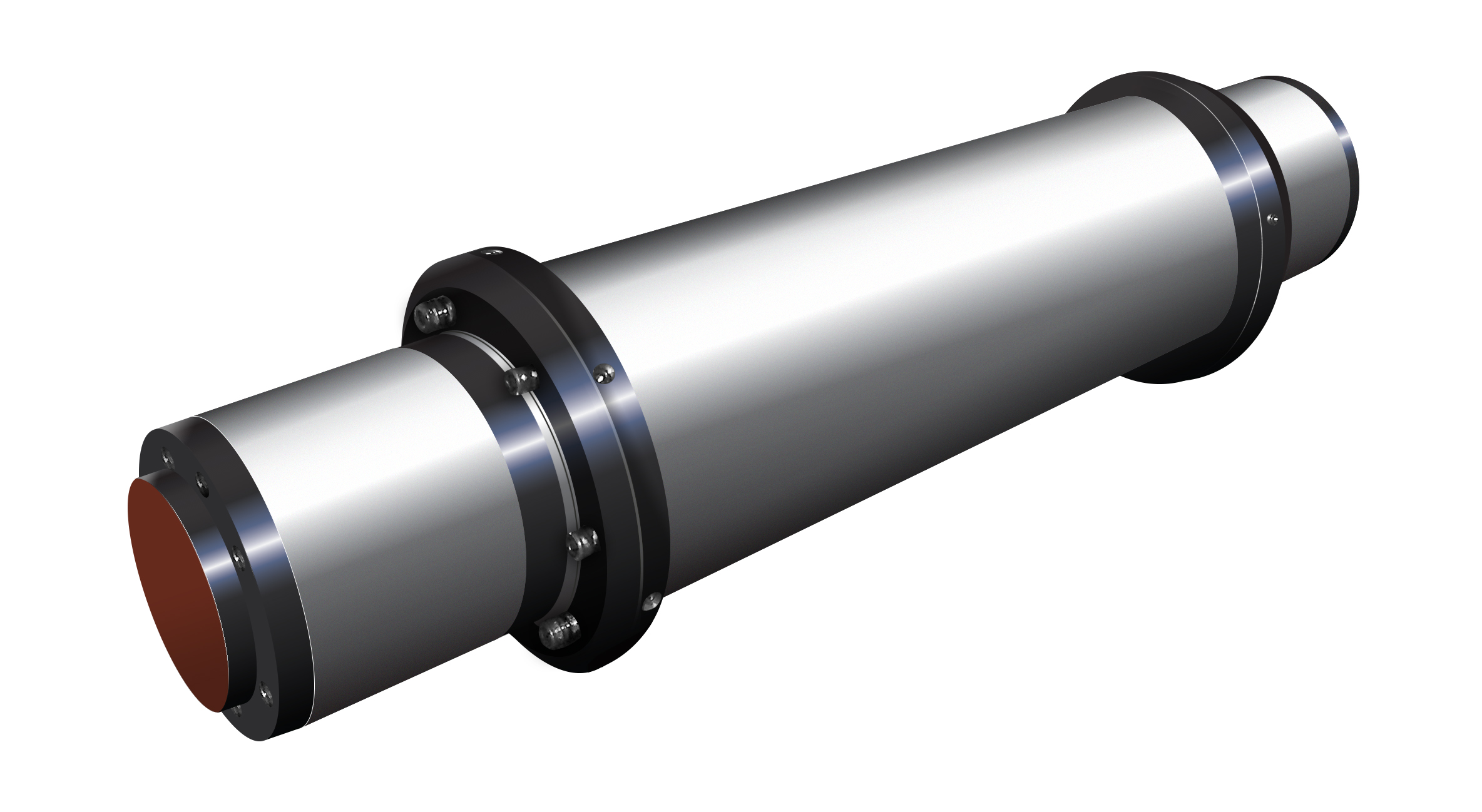

Your grinding operation runs smoothly until it doesn’t. One moment your grinder is producing precision parts, the next it’s making unusual noises and struggling to maintain proper feed rates. More often than not, the culprit lies within your hydraulic assemblies—the heart of your grinder that powers everything from workhead rotation to table movement and infeed … Why Replacing Worn Hydraulic Assemblies Is Key to Grinder Performance

Your grinding operation runs smoothly until it doesn’t. One moment your grinder is producing precision parts, the next it’s making unusual noises and struggling to maintain proper feed rates. More often than not, the culprit lies within your hydraulic assemblies—the heart of your grinder that powers everything from workhead rotation to table movement and infeed … Why Replacing Worn Hydraulic Assemblies Is Key to Grinder Performance