Why Grinder Performance Drops with Age and How Replacing Surface Grinder Parts Restores It

You’re midway through a crucial production run when your once-reliable surface grinder starts acting up. Surface finishes are inconsistent, grinding cycles are slower, or worse, scrap rates are climbing. Sound familiar? It’s easy to dismiss these issues as part of a machine’s aging process, but they might not be what they seem.

The truth is that surface grinders don’t lose their precision overnight. Subtle wear and tear on parts is often the hidden culprit behind declining performance. The good news? Upgrading or replacing surface grinder parts can restore your machine’s precision and productivity without having to purchase a brand-new machine.

What Happens as Surface Grinders Age?

Surface grinders are workhorses in any machining environment, regularly subjected to high usage. Over time, this demanding workload starts introducing wear patterns across critical components.

Even with regular maintenance, some wear is inevitable. Grinder parts like bearings, hydraulic systems, and precision screws gradually lose their tolerances. These changes are often incremental, which means shop owners may not immediately notice a decline in performance. However, small inaccuracies quickly snowball into bigger issues, impairing both production quality and efficiency.

Aging grinders also suffer from worn lubrication systems, which can result in uneven movement and accelerated component wear. This creates a vicious cycle that, left unchecked, can lead to major productivity setbacks.

What Are the Warning Signs Your Surface Grinder Parts Are Failing?

Don’t wait until your grinder stops in its tracks! Watch for these common signs of a grinder failure:

- Inconsistent Surface Finishes: When your surface finishes no longer meet exacting standards, it’s typically a sign that critical components like the spindle bearings or cross-feed screws are worn out.

- Grinding Burn or Overheating: Is your workpiece overheating during the grinding process? This is often caused by failing hydraulic valves or inconsistent magnetic chuck performance.

- Reduced Flatness and Parallelism: If your parts aren’t coming out flat or parallel, misaligned or deteriorating parts like the chuck controller or feed screws are likely to blame.

- Unexpected Vibration or Chatter: Excessive vibration isn’t just annoying; it’s a major indicator of failing way covers, inadequate lubrication, or faulty spindle bearings.

- Increased Scrap Rate or Slow Cycle Times: When precision drops, scrap rates rise. Long grinding cycles or inconsistent tolerances are often tied to multiple failing components, all quietly sabotaging throughput.

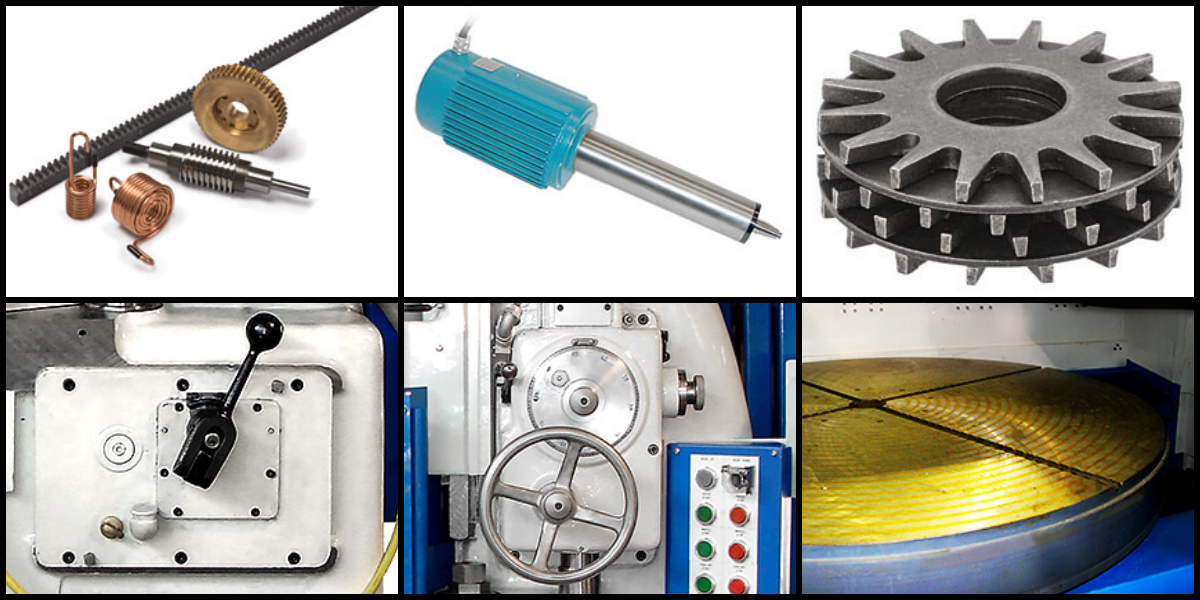

What Parts Commonly Cause Poor Grinding Accuracy?

Knowing which components are most susceptible to wear is key to understanding the most common causes of poor grinding accuracy:

- Hydraulic Valves: Critical for smooth and precise table movements. Worn valves can lead to jerky, inconsistent operation.

- Spindle Bearings: These ensure rotational precision. Their degradation often leads to chatter, overheating, or poor surface quality.

- Cross-Feed Screws & Nuts: Essential for precise positioning, these components lose accuracy over time, impairing surface parallelism.

- Magnetic Chucks or Chuck Controllers: Uneven clamping force causes inconsistent finishes and can damage workpieces.

- Way Covers & Lubrication Systems: Protecting moving parts from debris and wear, damaged covers or insufficient lubrication accelerates component abrasion.

Replacing these grinder components proactively has a dramatic impact on machine performance.

How Aging Parts Quietly Sabotage Your Productivity

Would you run a marathon in worn-out sneakers? Operating a grinder with failing components isn’t much different. Here’s how it impacts your shop’s bottom line:

- Increased Scrap = Increased Costs: Parts that fall outside spec waste material, time, and labor. Even minor inaccuracies can be costly when compounded over multiple runs.

- Longer Cycle Times = Less Output: Worn components slow down your machine’s efficiency, forcing extended cycle times. Over time, this bottleneck eats into production schedules.

- Emergency Downtime = Missed Deadlines: A neglected issue doesn’t stay small forever. Sudden failures result in costly downtime, forcing emergency repairs and potentially jeopardizing client trust.

How to Prioritize Surface Grinder Part Replacement

The key to minimizing disruption is addressing issues before they spiral out of control. Here’s how to create a grinder part replacement strategy that works.

- Start with High-Impact Components: Focus on parts that have the most direct impact on performance. Spindle bearings, hydraulic valves, and cross-feed screws should be the first to inspect and replace.

- Use a Simple Checklist: Evaluate your grinder’s performance regularly with these questions:

- Is there vibration or chatter?

- Are surface finishes uneven or inconsistent?

- Is positioning repeatability declining?

- Have scrap rates increased?

- Distinguish Urgent vs. Preventive Repairs: Parts in active failure mode (e.g., causing downtime or producing poor results) should be dealt with immediately. Components showing wear but still functional should be inspected regularly as part of your grinder maintenance plan.

Why Choose GCH Tool Group for Surface Grinder Spare Parts and Components?

Benefits of ordering your surface grinder spare parts and components from GCH Tool Group:

- Access to over 10,000 new in-stock parts and components assemblies for your surface grinder.

- Immediate phone or e-mail support.

- Expert advice while identifying the necessary surface grinder parts and components.

- Reduction in your stockholding costs.

- Same-day shipping, whenever possible.

Don’t Throw Away Precision. Restore It.

At GCH Tool Group, we specialize in replacing surface grinder parts and accessories, as well as providing grinder spare parts. From spindle bearings to way covers, our expertise ensures your machine operates as if it’s brand-new.

Explore our custom surface grinder parts! Request a quote today and experience the difference.