Make Your Centerless Blades Work for You

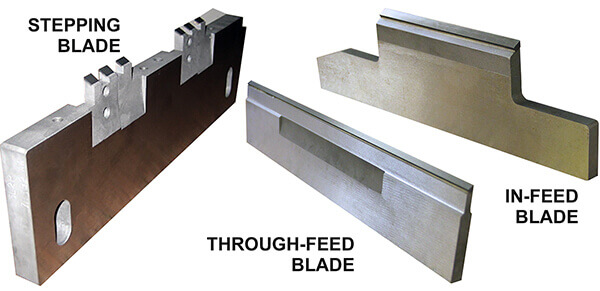

When it comes to centerless grinders, work blades can often be taken for granted. Spindle assemblies, accessories like filtration units or upgrades like servo infeed systems get a lot of attention, while the centerless blade is expected to just keep on working, grinding parts to the right size and shape.

But the proper selection of centerless blades, combined with appropriate use and care, will make sure these indispensable components function at optimal performance over the long haul.

There are three key factors in selecting the right blade:

· Grinder model number

· Diameter of the part being ground

· The material the part is made of

Choose the Right Part

The model number is important because there’s enough variation in the size of centerless grinder models that different machines sometimes require a work blade with a different width base and height. GCH Tool can support your centerless blade needs for any centerless grinder, including:

The diameter of the part directly affects the height of the blade. Parts with smaller diameters require the use of taller blades, while shorter blades are used for parts with wider diameters. If you don’t have a properly sized centerless blade, you will not have a good part.

Carbide-tipped blades usually work well for most applications, but certain part materials may require a different type of centerless blade. For instance, in grinding stainless steel parts, a bronze blade would be used, because stainless steel swarf builds up on carbide-tipped blades.

Help Available

GCH Tool has a vast array of standard centerless blades in stock, ready for shipment to your shop. And, if your needs are a bit non-standard, we can make a blade that’s right for your application.

Most importantly, we have the experience and expertise to understand your grinding needs and ensure you get the right work blade – right component of any kind, for that matter – for the job at hand. We don’t just match model number and blade and blindly ship the part. Instead, GCH Tool’s experts listen to your needs and provide the right solution for your situation.

In some cases, a new blade may not be the right answer. Sometimes, the centerless blade’s condition isn’t even the culprit. Improper mounting, such as poorly tightened fasteners, a debris-laden blade slot or incorrect blade height, can create problems that are correctable without having to replace the blade.

In other situations, the blade’s edge has been worn down or chipped, making it hard to keep a good part. Even then, complete replacement isn’t necessarily the immediate solution. Barring a serious mishap, work blades are notoriously long lasting and can be re-ground or re-tipped numerous times.

And GCH Tool has your back on centerless blade repairs and refinishing. We’ll inspect your blade and provide advice on the right route to take. If we find a chip or hairline crack, we won’t just repair that section. Partial repairs inevitably create a lip that will keep your machine from grinding consistent parts. We’ll re-work the entire blade length, ensuring the smooth finish you need to produce the high-quality parts your customers expect.

Full-Service Solutions

Of course, the blade edge is just one part of the equation. On every re-grinding and re-tipping job, we also re-grind the sides and base to ensure each surface is straight and true. And we don’t waste time – our turn-around is 7 to 10 days for re-grinding and 15 to 20 days for re-tipping.

Replace. Re-grind. Re-tip. Whatever your centerless work blade requirements are, GCH Tool can meet them. Call 586-777-6250 or email sales@gchtool.com for the assistance you need.