Place one call and access our extensive inventory of 10,000 new parts and components for all grinder types and brands

Get the Grinder Parts and Components You Need

Centerless Grinding Regulating Wheel Dressers

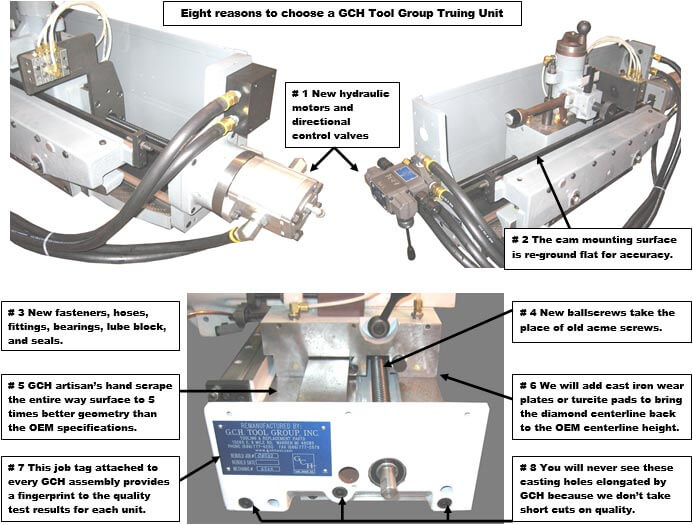

GCH provides regulating wheel dressers on exchange for all centerless grinding models. When remanufacturing grinder regulating wheel dressers, GCH follows stringent guidelines such as:

- Installing cast iron wear plates or Turcite® pads to bring the diamond centerline back to the OEM centerline height

- Precision hand-scraping and hand-flaking ways and gibs to better-than-new tolerances– up to five times better geometry than OEM specifications

- Regrinding the cam mounting surface flat for better accuracy

- Replacing the acme screw with a ball screw

- Using all new internal parts, including diamond bars, gibs and bellow covers

Variety of Options to Improve the Performance of Regulating Wheel Dressers

GCH also offers a variety of options to improve the performance of regulating wheel dressers on any centerless grinder brand, including Lidkoping, Bryant, Cincinnati Milacron, Gold Crown, Landis or Koyo. Options include:

- Electric servo motor to replace hydraulic motors on all axes

- Control valves for hydraulic truing

- Linear ways to replace gib ways

- Lube systems

- New fasteners, hoses, fittings, bearings and seals

There’s no short cut to quality at GCH Tool – you’ll never find elongated cast holes on one of our regulating wheel dressers.

As with all GCH Tool components, we test our dressers for no less than eight hours on test stands built to duplicate your operating conditions. We attach a job tag to every unit to provide a fingerprint to the quality test results for each assembly.

Learn more about our quality assurance program, which ensures our customers get the best-quality grinding regulating wheel dressers. Click here for a full list of our centerless grinder parts and components.

Speak with one of our experienced sales engineers