Grinding Wheel Dressers Keep Centerless Grinders Humming

Centerless grinding machines experience a lot of wear and tear over time, which can cause poor surface finishes and part quality. Truing and dressing throughout the grinding process can counteract those issues, enabling your centerless grinder to consistently produce parts with the required size and surface finish.

Truing and dressing the grinding wheel typically occur simultaneously to correct or alter the shape of the grinding wheel (truing) and to remove old grains and expose new sharp grains to assist in the cutting action of the abrasive (dressing).

Truing generally is done during the grinding process to correct the wheel profile from changes that naturally occur to its form during regular use. Truing also is done to prepare the grinding face of a new grinding wheel.

During the grinding process, standard dressing is done at frequencies determined by a number of factors, including the amount of material being removed, surface finish requirements, and accuracy of forms required on the grinding wheel.

Dressed for Success

There are several types of grinding wheel dressers: stationary, rotary diamond disc and rotary diamond roll.

Stationary dressing tools are pretty common and typically provide a long dressing time, flexible shape, and short diamond life.

Production centerless grinding usually benefits from the use of rotary grinding wheel dressers, which provide a more consistent process. Rotary dressing tools also allow for more abrasive selections, including high ceramic concentration and superabrasive wheels. A rotary diamond disc has a medium dressing time, flexible shape, and long diamond life. A rotary diamond roll has a short dressing time, fixed shape and long diamond life.

What you use to dress the wheel is entirely dependent on whether the grinding wheel needs to be trued or dressed, the required cycle time and other factors. Diamonds are used in the grinding wheel dresser to true and dress the grinding wheel. The size or carat of diamond to be used or whether a single diamond or multiple diamonds will be required is determined by the wheel size, whether it has a resin bond and whether it uses a premium abrasive.

Also Read: The Role of Hydraulic Assemblies in Centerless Grinding

Go to the Centerless Grinding Experts

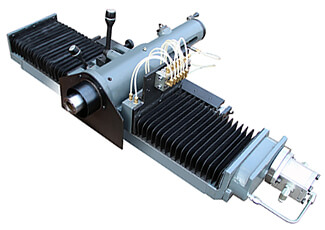

GCH Tool offers significant expertise in the centerless grinding process, including the care and maintenance of grinding wheel dressers. Our grinding wheel dresser assemblies are available on exchange for all brands of centerless grinders, including Cincinnati Milacron, Landis, Gold Crown and Bryant. We also offer diamond tools used to condition and true grinding wheels.

Contact GCH Tool for your centerless grinder maintenance requirements.