Everything You Need to Know About Diamond Grinding Wheel Dressers

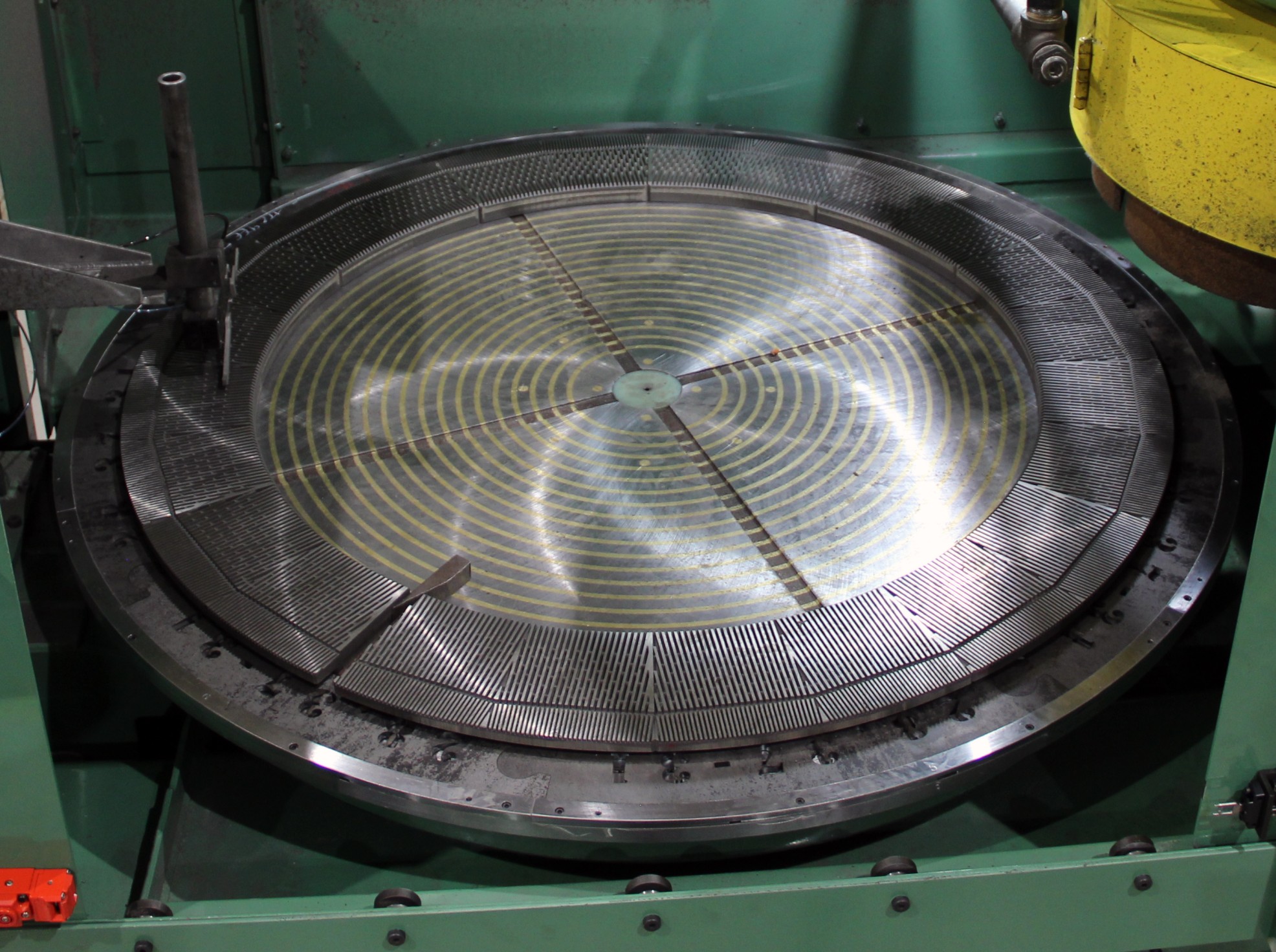

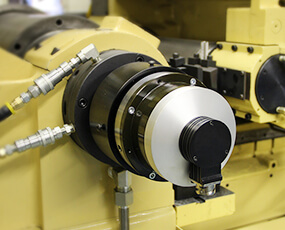

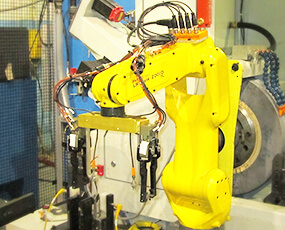

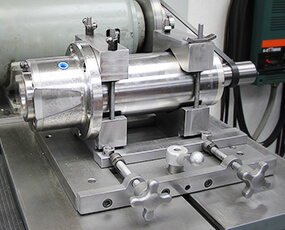

The surface of a grinding wheel can be trimmed or dressed using a diamond grinding wheel dresser. A diamond grinding wheel dresser is a wonderful tool to use to maintain wheels properly. It aids in altering or restoring a wheel’s original construction. Additionally, it is utilized to make grinding wheels’ sharp corners again and it … Everything You Need to Know About Diamond Grinding Wheel Dressers

The surface of a grinding wheel can be trimmed or dressed using a diamond grinding wheel dresser. A diamond grinding wheel dresser is a wonderful tool to use to maintain wheels properly. It aids in altering or restoring a wheel’s original construction. Additionally, it is utilized to make grinding wheels’ sharp corners again and it … Everything You Need to Know About Diamond Grinding Wheel Dressers