Magnetic Chucks for Grinding: Introduction, Types & Benefits

When you use magnetic chucks for grinding, you can get the peace of mind that your grinding jobs will be more precise and leave less to chance/leave you vulnerable to slip ups. Read on to learn more about magnetic chucks for grinding.

What are Magnetic Chucks?

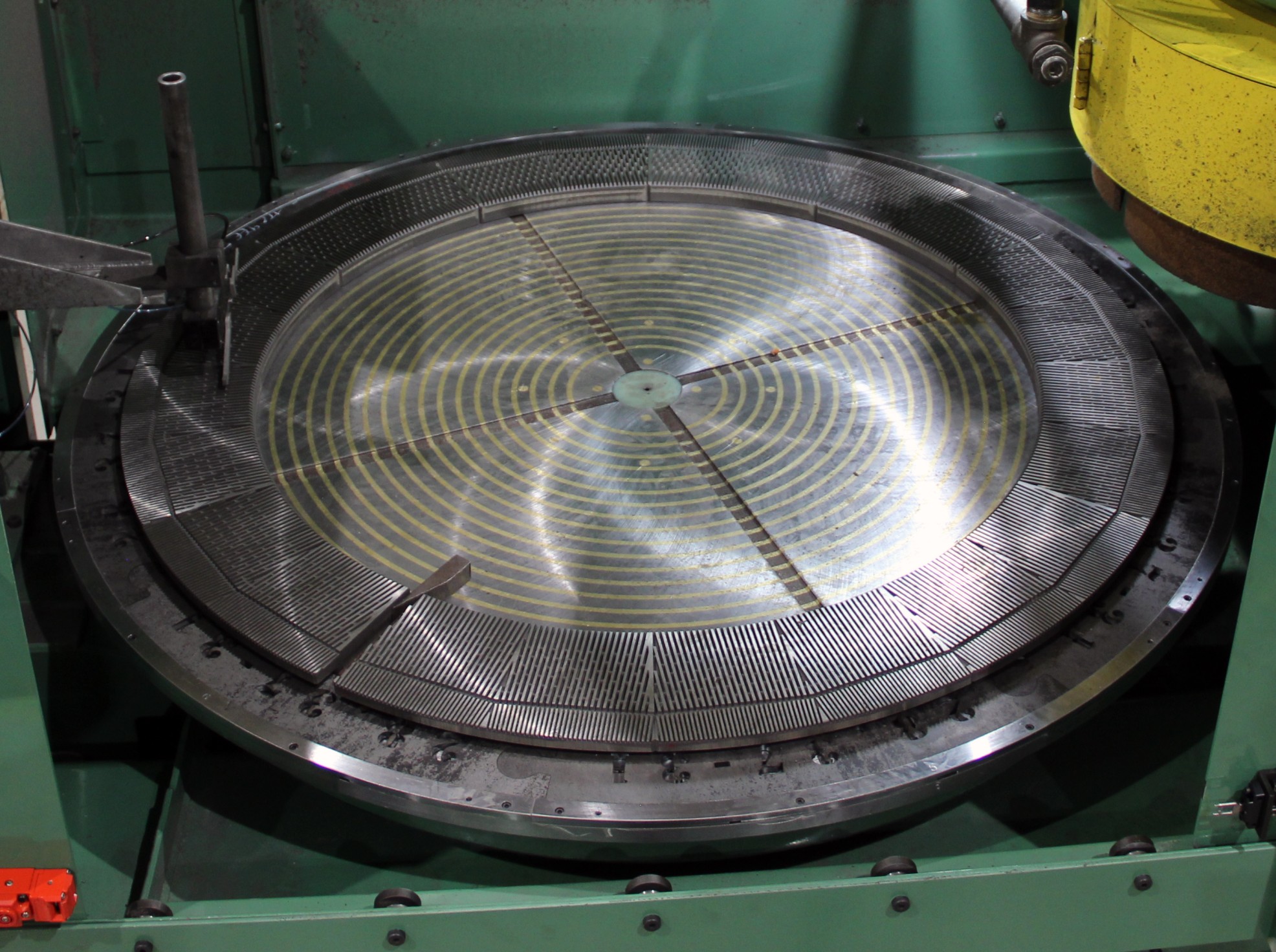

Much as it sounds, a magnetic chuck uses magnetic fields on metal objects to hold them in place during machining. Essentially, you need whatever you’re machining to be fixed and stable while the grinding machine goes to work, and a magnetic chuck helps you achieve that.

Types of Magnetic Chucks

While magnetic chucks for grinding are more or less simple in principle, they do come in several varieties.

Permanent Magnetic Chuck

This is a magnetic chuck that has permanent poles—in other words, it is always exercising a magnetic pull on objects, even when you’re not machining.

Electromagnetic Chuck

This chuck will only exercise a magnetic draw on objects when a current is passed through it (thus the name “electromagnetic”). The ability to turn the magnetism on or off at will allows you to adjust the workpiece you’re machining more easily. The one drawback is that due to the need of an electric current passing through the magnetic chuck for it have a magnetic draw, should the current stop, the workpiece will fall, potentially putting workers at risk. There are, however, safety contingencies that you can take to ensure your personnel are protected.

Electro-Permanent Magnetic Chuck

A hybrid of the two types above, this type of chuck uses a jolt of electricity to lock in a workpiece and a jolt to release it. This ensures that should there be a power outage or the chuck, for whatever reason, is no longer able to receive a current, it will still hold onto the workpiece. You can also adjust the level of magnetism you want this chuck to exert, providing flexibility.

Benefits of Using Magnetic Chucks in Grinding

Magnetic chucks are excellent grinding accessories as they help to ensure precision and safety. With the ability to modify the products’ placement in addition to a hard locking of the workpiece in place, your machining will be done faster, you will face less downtime, and your work will be more precise.

Order Magnetic Chuck Assembly and Other Grinder Tools from GCH Tool Group Inc.

Whether you’re in need of magnetic chucks for grinding, grinding accessories, grinding parts, or grinder repair, we can manage all of your needs at GCH Tool Group.

We host the world’s largest inventory of new spare parts and components for grinders, so you can rest assured that whatever you need, we almost certainly have it—and can get it to you fast.

We’re also experts in centerless grinder automation, so you can get the best grinding rig for your business.

Fill out our RFQ form to get quick, knowledgeable assistance from an experienced sales engineers for your grinder parts and components needs. Our quick response and expert advice will keep your production running 24/7.