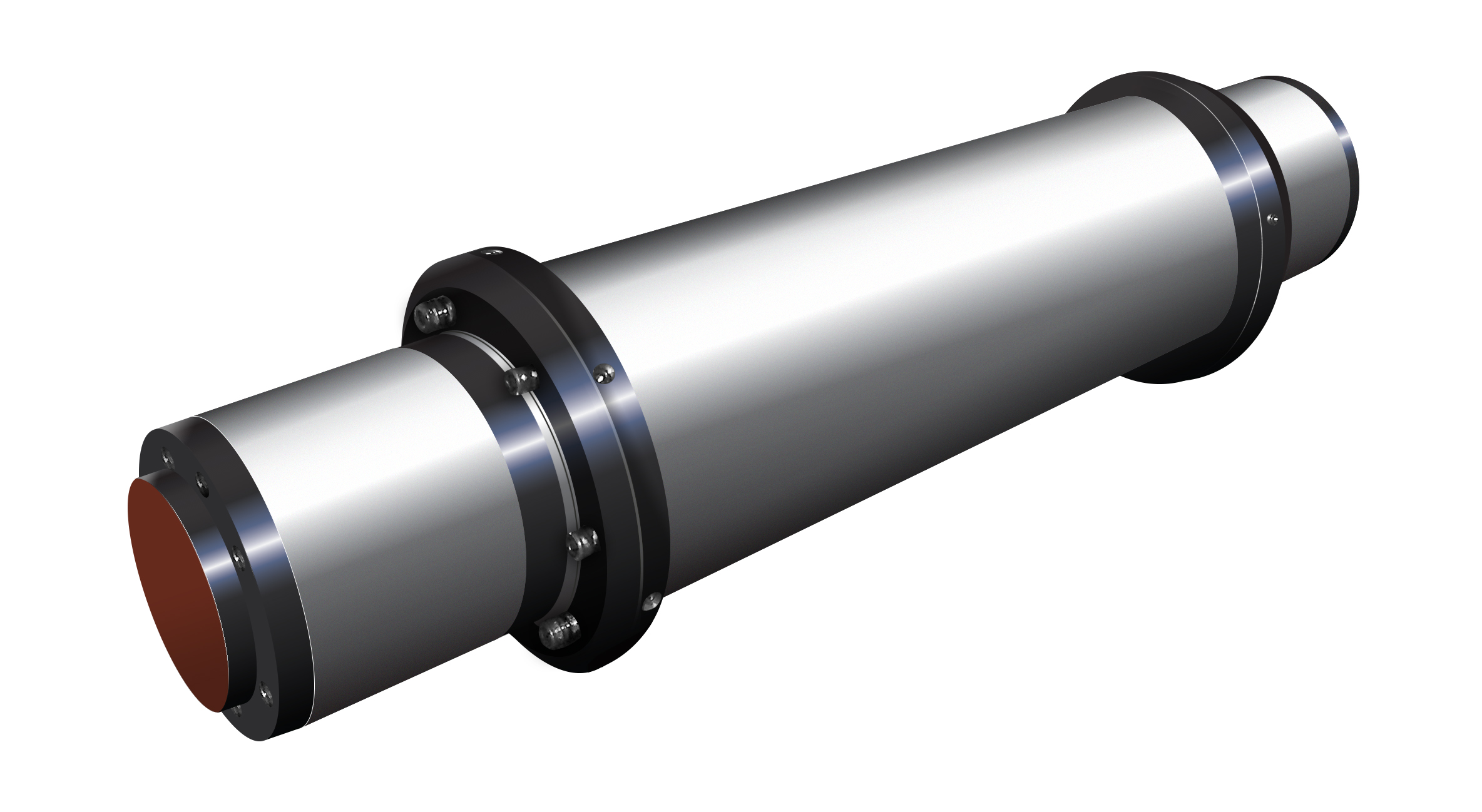

Everything You Need to Know About CNC Spindles

CNC spindles play a vital role in the efficiency and accuracy of the manufacturing process, shaping raw materials into precise and complex parts with ease. In this article, we will explore the ins and outs of CNC spindles, from the different types and how they work to the key factors to consider when selecting the right … Everything You Need to Know About CNC Spindles

CNC spindles play a vital role in the efficiency and accuracy of the manufacturing process, shaping raw materials into precise and complex parts with ease. In this article, we will explore the ins and outs of CNC spindles, from the different types and how they work to the key factors to consider when selecting the right … Everything You Need to Know About CNC Spindles