Everything You Need to Know About CNC Spindles

CNC spindles play a vital role in the efficiency and accuracy of the manufacturing process, shaping raw materials into precise and complex parts with ease. In this article, we will explore the ins and outs of CNC spindles, from the different types and how they work to the key factors to consider when selecting the right one for your specific needs and how to extend their lifespan.

Whether you’re a professional or new to the world of CNC, this comprehensive guide has something for everyone. So let’s dive in and uncover the full potential of CNC spindles!

What Is a CNC Spindle and How Does It Work?

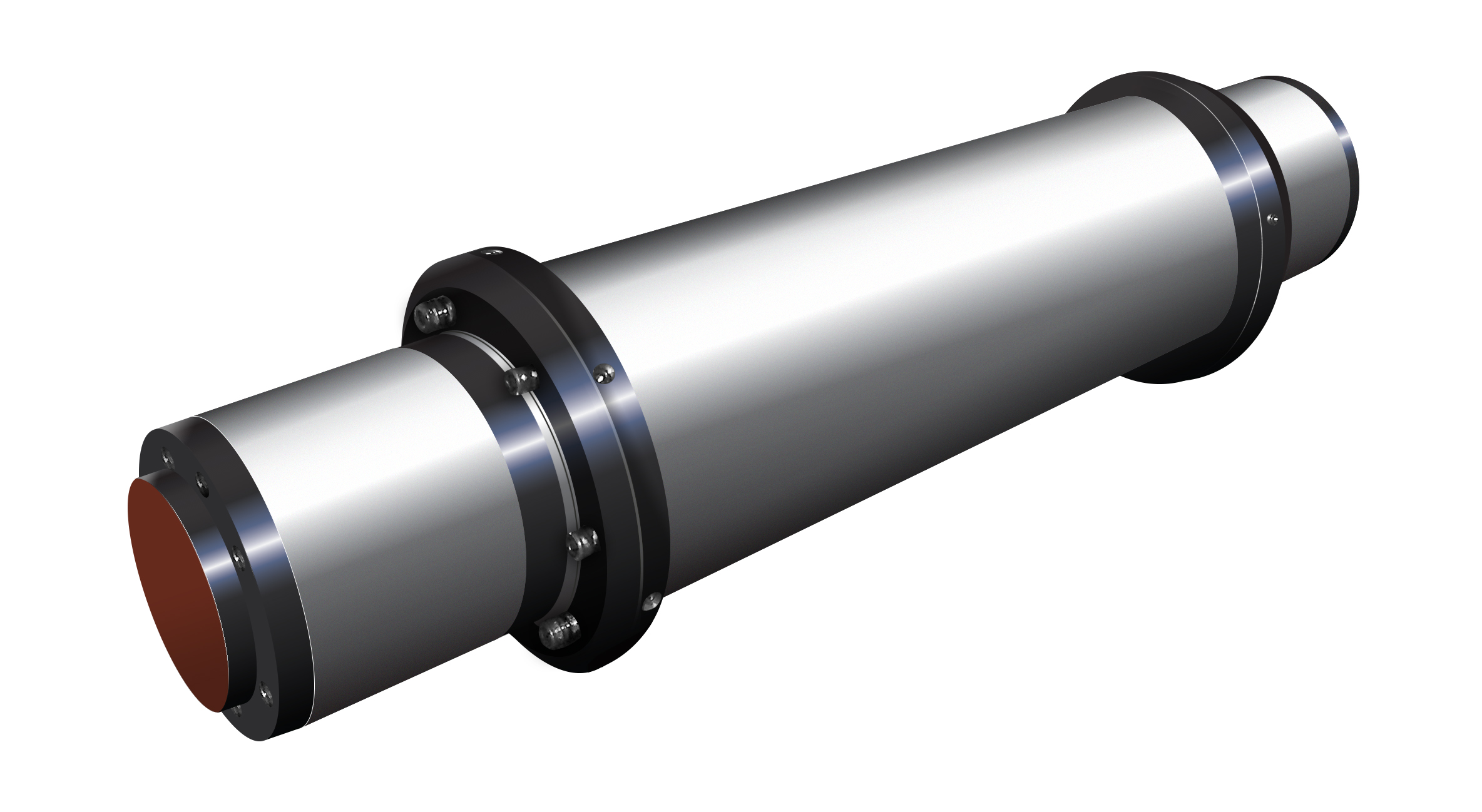

A CNC spindle is a vital machine component used in many industries, such as automotive and aerospace. It consists of an electric or air-powered motor with a shaft that holds the tool in place, and a taper for controlling various tools.

The spindle rotates on an axis that can be manually or computer-controlled to perform cutting, slicing, refining and other operations. Spindles come in different sizes to meet various needs.

Things to Consider when Choosing a CNC Spindle

Here are the major factors to consider when choosing CNC spindles:

Application of Spindle in Various Industries

Choose a CNC spindle based on the specific tasks it will be used for. Consider factors like maximum speed and torque capacity.

Spindles by CNC Machine Type

Also consider the type of CNC machine the spindle will be used with. Here are the most common types:

- CNC mills, which utilize G-code or other languages and are used in the manufacturing industry.

- CNC lathes, which are used for complex, intricate cutting and require high velocity.

- CNC plasma cutters, which use compressed-air gas and electrical arcs to cut metal in metal fabrication shops.

- EDM (electric discharge machines), which are used for molding pieces using electrical sparks.

- CNC water jets, which are used in metal shops and for cutting and shaping. They use high-pressure water sprayed through a hard substance.

Spindles by Material Use

Choose a CNC spindle based on the materials it will be used with. Hard materials may require a higher torque capacity and a more rigid design, while softer materials may allow for a lower torque capacity and a more flexible design. When selecting a CNC spindle, it is important to choose one that has the right RPM, power, and cooling capabilities for your specific material.

How to Extend Your CNC Spindle’s Life

The following guidelines can help you extend the life of your CNC spindle.

Find out when a Repair Is Needed

One of the key ways to extend the life of your CNC spindle is to find out when a repair is needed before the system fails. This can be done through regular maintenance and inspections, which can help to identify potential issues such as vibration or chatter levels before resulting in serious problems.

Check for Innovation and Improvements

Another way to extend the life of your CNC spindle is to stay up to date on the latest innovations and improvements in spindle technology. By adopting new technologies and techniques, you can improve the performance and reliability of your spindle, helping to extend its life.

Create Failure Reports

Another important thing is to get reports of tests carried out on your spindle. At GCH Tool Group, we prioritize quality and transparency. To help our customers understand the root causes of any failures and take steps to prevent future issues, we provide comprehensive failure reports.

These reports feature detailed written descriptions and photographs of the causes of the failure, as well as recommendations for prevention. With this information, our customers can extend the lifespan of their spindles by implementing preventative measures based on the specific causes of failure.

Schedule Advanced Testing and Verification

Conducting thorough testing and verification on remanufactured spindles to ensure their quality and reliability is also crucial. This should include vibration analysis, closed-loop testing, encoder alignment, various sensor tests and running the spindle at its designed operating speeds to ensure proper performance. Then, detailed reports should be generated afterwards by quality assurance technicians to confirm that the spindle is of good quality.

Consider a Retrofitting or Rebuilding Service

If your CNC spindle is experiencing serious issues or is reaching the end of its life, you may want to consider a retrofitting or rebuilding service. This can help to extend the life of your spindle by replacing worn or damaged components, or by upgrading to newer technologies so you can get more value out of your CNC spindle and keep it operating at its best for as long as possible.

How GCH Tool Group’s CNC Spindle Services Can Help You

Maintaining your CNC machine is crucial for optimal performance, and understanding the programming behind it is just as important. However, even the most careful operator may encounter issues with their machine spindles. That is where the GCH Tool Group comes in.

We offer high-quality spindle repair services to help you keep your equipment in top condition. Don’t let defective spindles cause problems with your machine—let professionals help you keep it running smoothly.

Also Read: The Benefits of Using Long Bar Attachments for Grinding Machines

GCH Offers the World’s Largest Inventory of CNC Spindles

At GCH Tool Group, we carry the following grinder brands: Cincinnati Milacron, Bryant, Chiron, Colonial, Fischer, GMN, Heller, IBAG, Kessler, Kingsbury, Mag, Makino, Mazak, Mori Seiki, Okamoto, OKK, Okuma, Parker Majestic, Pope, Setco, Toyoda, Weiss and Whiton Spindle.

Contact GCH Tool Group to Extend the Life of Your CNC Spindles

CNC spindle repair and rebuilding is a cost-effective way to extend the life of your spindles and boost your manufacturing processes. By investing in these services, you can save money on new spindles and minimize downtime. Plus, a well-maintained spindle operates more efficiently, resulting in improved machine performance and overall productivity.

So, why not rely on GCH Tool Group’s CNC spindle repair and rebuilding services to maximize the value of your equipment and enhance your company’s performance? Contact us today for more information.