How Automation and Loaders Can Improve the Efficiency and Productivity of Your Grinding Operations

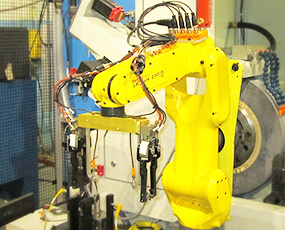

Automating your grinding operations could be the key to unlocking unprecedented levels of efficiency and productivity. Automation refers to the use of machinery to carry out tasks normally performed by humans, while loaders are devices designed to move materials, such as raw materials or finished products, from one place to another. By integrating automation and … How Automation and Loaders Can Improve the Efficiency and Productivity of Your Grinding Operations

Automating your grinding operations could be the key to unlocking unprecedented levels of efficiency and productivity. Automation refers to the use of machinery to carry out tasks normally performed by humans, while loaders are devices designed to move materials, such as raw materials or finished products, from one place to another. By integrating automation and … How Automation and Loaders Can Improve the Efficiency and Productivity of Your Grinding Operations