Common Signs That Your CNC Spindle Needs Repair

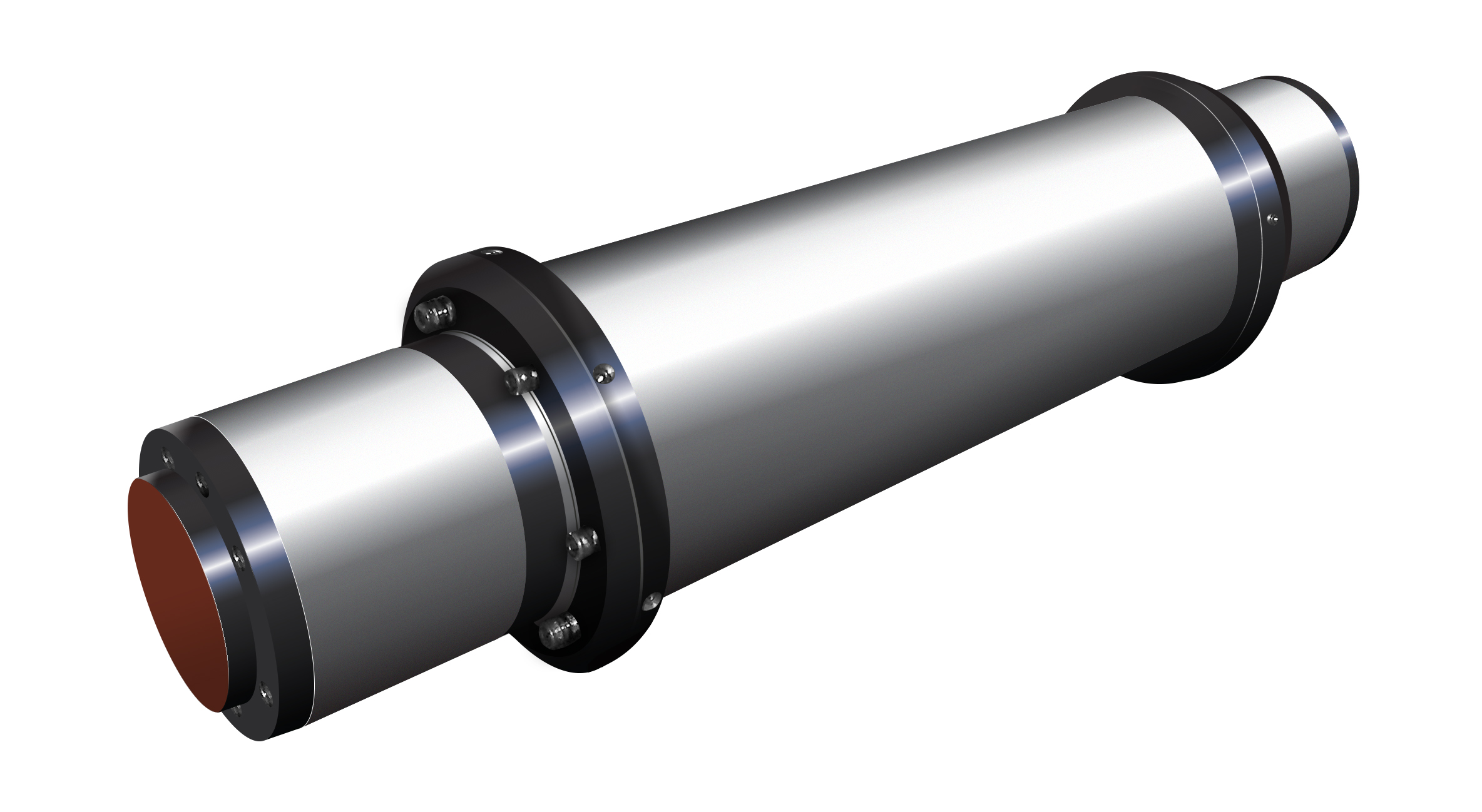

Grinder spindles are like any other machine part; they naturally wear out and require repair over time. Hence, it is important to identify signs of spindle issues in your machines to ensure the smooth and efficient operation of your manufacturing processes. The machine tool can perform its functions accurately only when the spindle is in good condition.

One common sign that your spindle needs repair is abnormal noise coming from the bearings. Another sign to watch out for is chatter in the finished parts, which can compromise the quality of your products. Ignoring these signs can lead to downtimes or damage to the machine, which can be avoided if they are fixed promptly.

5 Signs of CNC Spindle Failure

CNC Spindles are the powerhouse of grinding machines, and they can fail due to many reasons. While bearing failure is one of the most common causes of spindle failure, some signs can indicate something is not right with your spindle. It is important to pay attention to the following signs as they may indicate that it needs a repair.

Unusual Noises

Unusual noise in your machine spindle indicates it is beginning to fail and may require repair. The noise could be caused by insufficient lubrication on the bearings, using the wrong type of lubricant or other causes. You should be familiar with the sound noise level of your spindle. This will allow you to promptly identify any unusual noise it makes.

Excessive Vibration

Worn components like bearings, drive belts, or gears can cause vibrations in the machine. For example, if a roller bearing race becomes pitted, the rollers will vibrate as they traverse the damaged area. Excessive vibration can also be caused by misaligned spindle components, which can reduce the machine’s lifespan and result in unplanned downtime.

Decreased Performance

If you notice variations in the surface finish of your machined parts or inconsistencies in dimensions, it could be caused by spindle problems. A malfunctioning spindle may exhibit fluctuating speeds during operation, resulting in irregularities or errors in the finished products. The best thing to do is to have it repaired immediately by a trusted spindle repair service provider.

Temperature Increase

Another crucial thing to monitor in your spindle is the temperature. It is essential for assessing bearing condition. While high-speed spindle bearings can reach temperatures over 113°F during normal operation, a significant temperature increase may indicate bearing breakdown. A non-contact infrared temperature gauge can be used to measure the temperature.

Leaks and Contamination

If you begin to notice oil or coolant around the spindle area, it means there is a damaged component leaking within the spindle assembly and this can allow different fluids and particles to enter and contaminate the system.

How Can Spindle Failures Be Prevented?

Taking proactive measures is more effective than dealing with the consequences. Regular maintenance is the best way to prevent spindle failure and save the avoidable cost of replacement. A maintenance schedule that includes regular inspections, cleaning and proper lubrication is essential.

Another key thing to prevent spindle failure is proper lubrication of the spindle is another key aspect of preventing spindle failures. Following the manufacturer’s guidelines for lubrication is essential, ensuring the correct type and amount of lubricant is used. Inadequate lubrication can increase friction and wear, while over-lubrication can cause excessive heat buildup.

Operator training is also vital for preventing spindle failures. Spindles can be sensitive to mishandling, which is why proper training of the machine operators is important.

What Makes GCH Tool Group’s CNC Spindle Repair and Rebuild Unique?

GCH Tool Group is a brand to partner with if you notice your spindle needs a repair or a rebuild. Our spindle repair services include varieties of machinery such as lathes, mills, grinders and CNC machinery.

If you allow us handle your spindle repair or rebuild, you get:

- Failure analysis report

- Hi-Pot test all motors

- 10000 Class clean room

- Vibration data

- Run closed loop (Siemens/Bosch (Indramat)/FANUC)

- In-house machining (better control of delivery)

- State-of-the-art gaging

- Final inspection reports

- Video of runoff

Should your spindle be beyond repair and you need a replacement right away, we offer different types of spindles and spindle assemblies.

Contact GCH Tool Group for CNC Spindle Repair

Identifying common signs of CNC spindle issues such as high temperature, decreased performance, leaks, unusual noise and excessive vibration and addressing them promptly is crucial for ensuring your spindle’s optimal performance and longevity.

Partnering with a spindle repair service provider like GCH Tool Group with years of experience working with many spindles brands such as Cincinnati Milacron, Okuma, Bryant, Chiron, Toyoda Fischer, GMN Weiss, IBAG and a host of others is important to ensuring your spindle works perfectly and last longer. Contact us now!