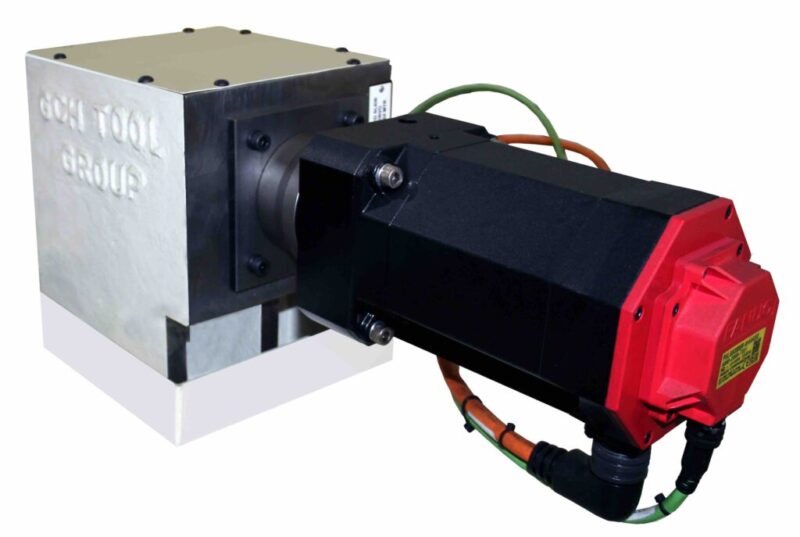

CNC Spindle Remanufacturing: Ensuring Precision and Performance

CNC spindles are the heart of any precision machining operation. They are critical in achieving the high accuracy and consistency required for complex manufacturing tasks. However, like all mechanical components, CNC spindles wear out over time. This is where remanufacturing comes into play. It’s a sustainable solution that not only restores spindle performance to its … CNC Spindle Remanufacturing: Ensuring Precision and Performance

CNC spindles are the heart of any precision machining operation. They are critical in achieving the high accuracy and consistency required for complex manufacturing tasks. However, like all mechanical components, CNC spindles wear out over time. This is where remanufacturing comes into play. It’s a sustainable solution that not only restores spindle performance to its … CNC Spindle Remanufacturing: Ensuring Precision and Performance