Grinder Parts and Accessories for Specialized Grinding Applications

In the world of manufacturing, precision is key. Specialized grinding applications are indispensable in industries ranging from aerospace to medical device manufacturing. The efficiency and reliability of these processes depend heavily on the grinder parts and accessories utilized. This blog post explores the significance of these components and provides insights into optimizing grinder parts and accessories for specialized grinding applications.

Understanding Specialized Grinding Applications

Specialized grinding applications involve unique and precise tasks catering to specific industry needs. These applications often require high accuracy, intricate shapes and the ability to handle challenging materials. Industries like aerospace, medical device manufacturing and tool and die making rely heavily on specialized grinding.

In specialized grinding, one size does not fit all. Customization is crucial for addressing the unique challenges of each application. By selecting the right grinding machine parts and accessories, you can enhance precision, improve efficiency and extend the lifespan of your grinding equipment.

Essential Grinder Parts for Specialized Applications

Customized grinder parts are essential in ensuring that your specialized grinding applications meet the exacting standards required in various high-precision industries.

Spindles and Bearings

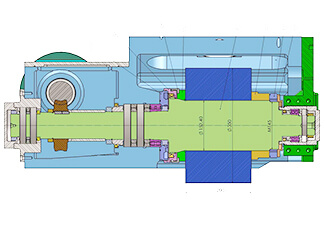

High-Precision Spindles

Spindles play a vital role in maintaining accuracy and consistency in grinding operations. High-precision spindles minimize runout and vibration, ensuring smooth and accurate grinding. Choosing the right spindle is essential for achieving the desired results in specialized applications.

Robust Bearings

Bearings support the spindles and are crucial for maintaining optimum speed and accuracy. Angular contact bearings and ceramic bearings are recommended for specialized applications due to their durability and performance consistency.

Angular contact bearings are particularly effective in handling combined loads, while ceramic bearings offer superior resistance to heat and corrosion, making them ideal for high-speed and high-temperature environments.

Grinding Wheels

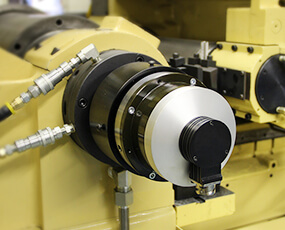

Customized Grinding Wheels

The choice of grinding wheel significantly impacts the grinding process. Customized grinding wheels, such as diamond wheels and carbon boron nitride (CBN) wheels, are designed for specific materials and processes.

Diamond wheels, for example, are ideal for cutting hard materials like ceramics, glass and carbide. CBN wheels are best suited for grinding ferrous metals. Both types enhance precision and efficiency in specialized grinding applications.

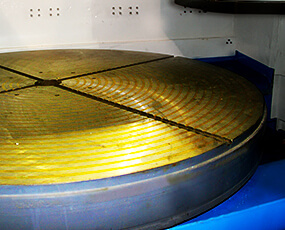

Wheel Balancing Systems

Maintaining wheel balance is essential for precision and tool life. Wheel balancing systems help achieve this balance, reducing vibrations and ensuring consistent grinding performance.

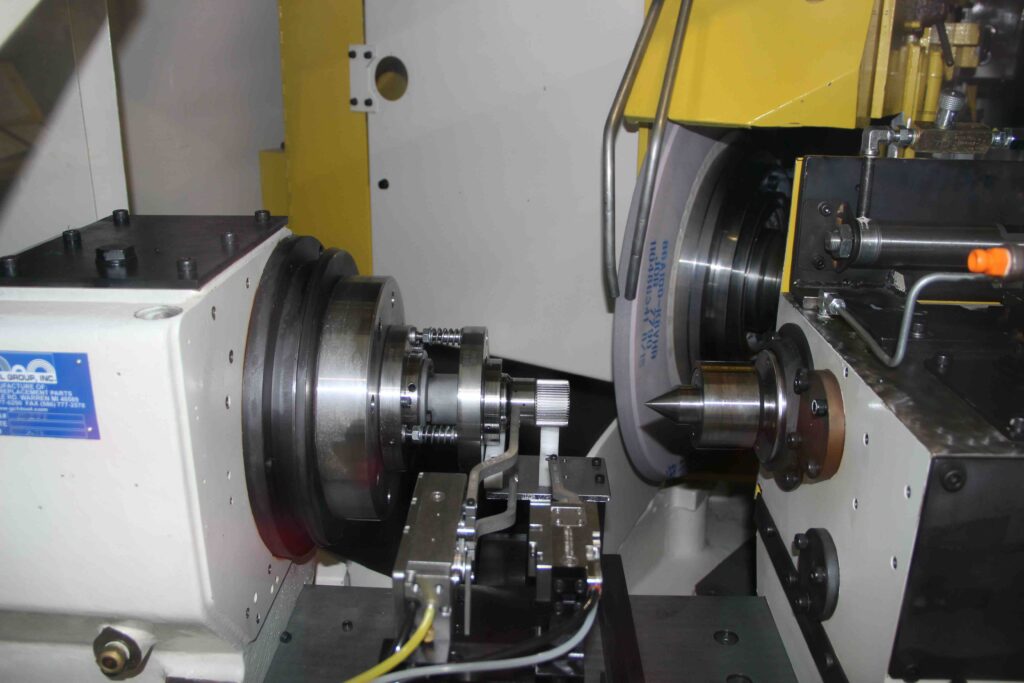

Workholding Devices

Magnetic Chucks

Magnetic chucks are ideal for holding ferromagnetic workpieces during grinding. They offer adjustable magnetic force and improve stability, ensuring precise grinding for specialized applications.

Grinding Fixtures

For non-magnetic or irregularly shaped workpieces, custom grinding fixtures provide the necessary support and stability. These fixtures ensure that the workpiece is firmly held in place, reducing the risk of errors.

Must-Have Grinder Accessories for Specialized Applications

When it comes to optimizing specialized grinding applications, having the right grinder accessories is just as important as choosing the correct grinder parts.

Coolant Systems

High-Pressure Coolant Systems

Coolant systems play a crucial role in preventing overheating and maintaining surface integrity during grinding. High-pressure coolant systems are especially beneficial in specialized applications, as they improve cooling efficiency and prolong tool life.

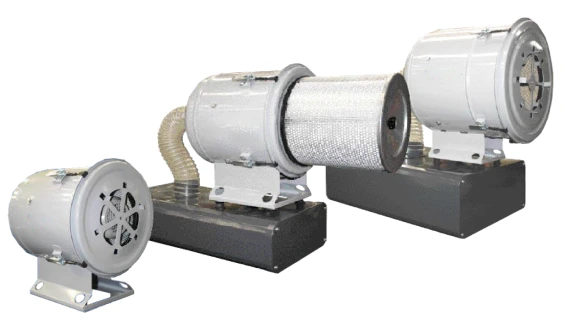

Mist Collectors

Maintaining a clean and safe workspace is essential in any grinding operation. Mist collectors capture and filter fine particles, ensuring a healthier environment for operators and reducing the risk of contamination.

Dressing Tools

Rotary Dressers

Rotary dressers are used to shape and profile grinding wheels. Customized rotary dressers ensure that the grinding wheels meet specific profile requirements, enhancing precision and efficiency.

Diamond Dressing Tool

Diamond dressing tools are known for their durability and performance consistency. They are ideal for creating intricate shapes and achieving fine surface finishes in specialized grinding applications.

Automation and Monitoring Systems

In-Process Gauging

In-process gauging systems provide real-time monitoring of the grinding process. These systems help maintain dimensional accuracy, ensuring that the final product meets the required specifications.

CNC Systems

Computer numerical control (CNC) systems offer advanced automation and flexibility in grinding operations. They are essential for producing complex shapes and profiles, enhancing the overall efficiency and precision of specialized grinding applications.

Also Read: Upgrading Your Grinder: Key Components to Consider

Choosing the Right Supplier for Your Grinder Parts and Accessories

Selecting a reliable supplier is crucial for ensuring the quality and performance of your grinding machine’s parts and accessories. GCH Tool Group offers a wide range of high-quality grinder parts, components and accessories for specialized grinding applications. Our commitment to customer satisfaction and support makes us a trusted partner for your grinding needs.

Contact GCH Tool Group Today!

In specialized grinding applications, the right grinder parts and accessories make all the difference. By investing in high-quality components and customizing them to your needs, you can enhance precision, improve efficiency and extend the lifespan of your grinding equipment.

Contact GCH Tool Group for more information and support. Enhance your grinding operations with our superior parts and accessories.