Grinding Wheel Dressers Keep Centerless Grinders Humming

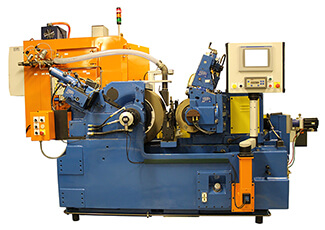

Centerless grinding machines experience a lot of wear and tear over time, which can cause poor surface finishes and part quality. Truing and dressing throughout the grinding process can counteract those issues, enabling your centerless grinder to consistently produce parts with the required size and surface finish. Truing and dressing the grinding wheel typically occur … Grinding Wheel Dressers Keep Centerless Grinders Humming

Centerless grinding machines experience a lot of wear and tear over time, which can cause poor surface finishes and part quality. Truing and dressing throughout the grinding process can counteract those issues, enabling your centerless grinder to consistently produce parts with the required size and surface finish. Truing and dressing the grinding wheel typically occur … Grinding Wheel Dressers Keep Centerless Grinders Humming