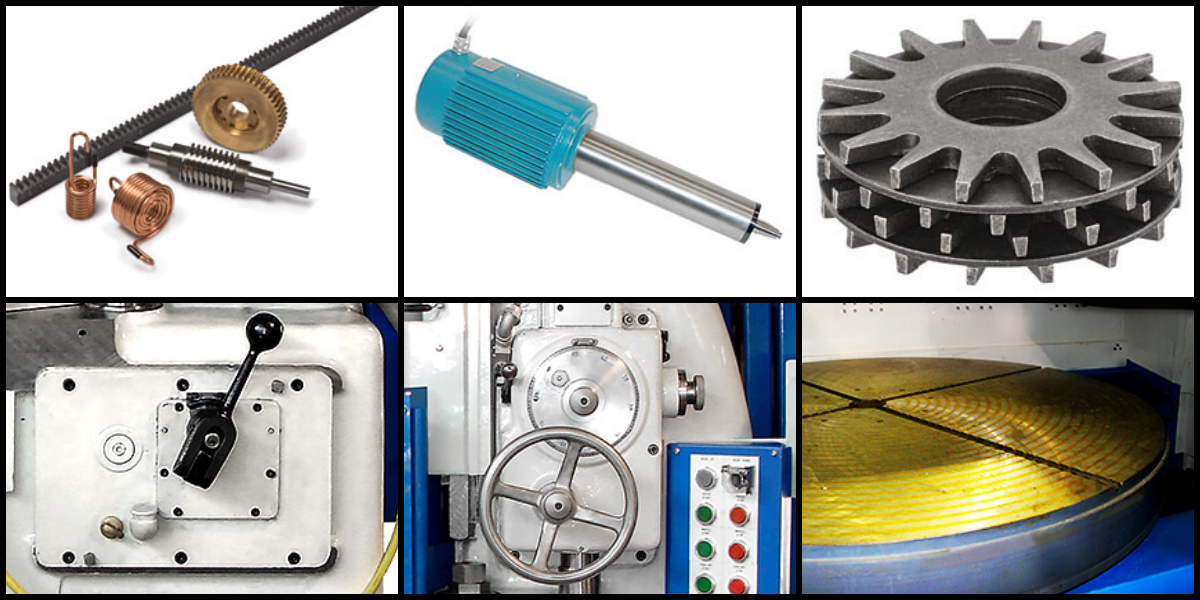

The Role of Hydraulic Assemblies in Centerless Grinding

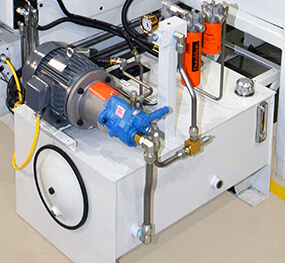

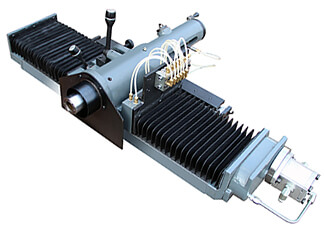

Centerless grinding is an indispensable machining process that ensures high-quality surface finishes. Central to this discipline is the hydraulic assembly—a silent yet powerful force behind this mechanical refinement. These assemblies..